Go Inspire Solutions Ltd is one of the UK’s leading direct mail suppliers and required a print trim extraction and heat recovery solution at its head office in Leicester, UK.

Go Inspire recently contracted Impact Air Systems to install a waste trim extraction system and hot air exhaust to its new HP T240 & T400 digital presses at its Leicester facility. These high-speed digital presses require a centralised waste extraction system to remove the process waste from the multiple production lines, as well as a ducted system to extract the hot air generated by the drying systems on each of the HP machines.

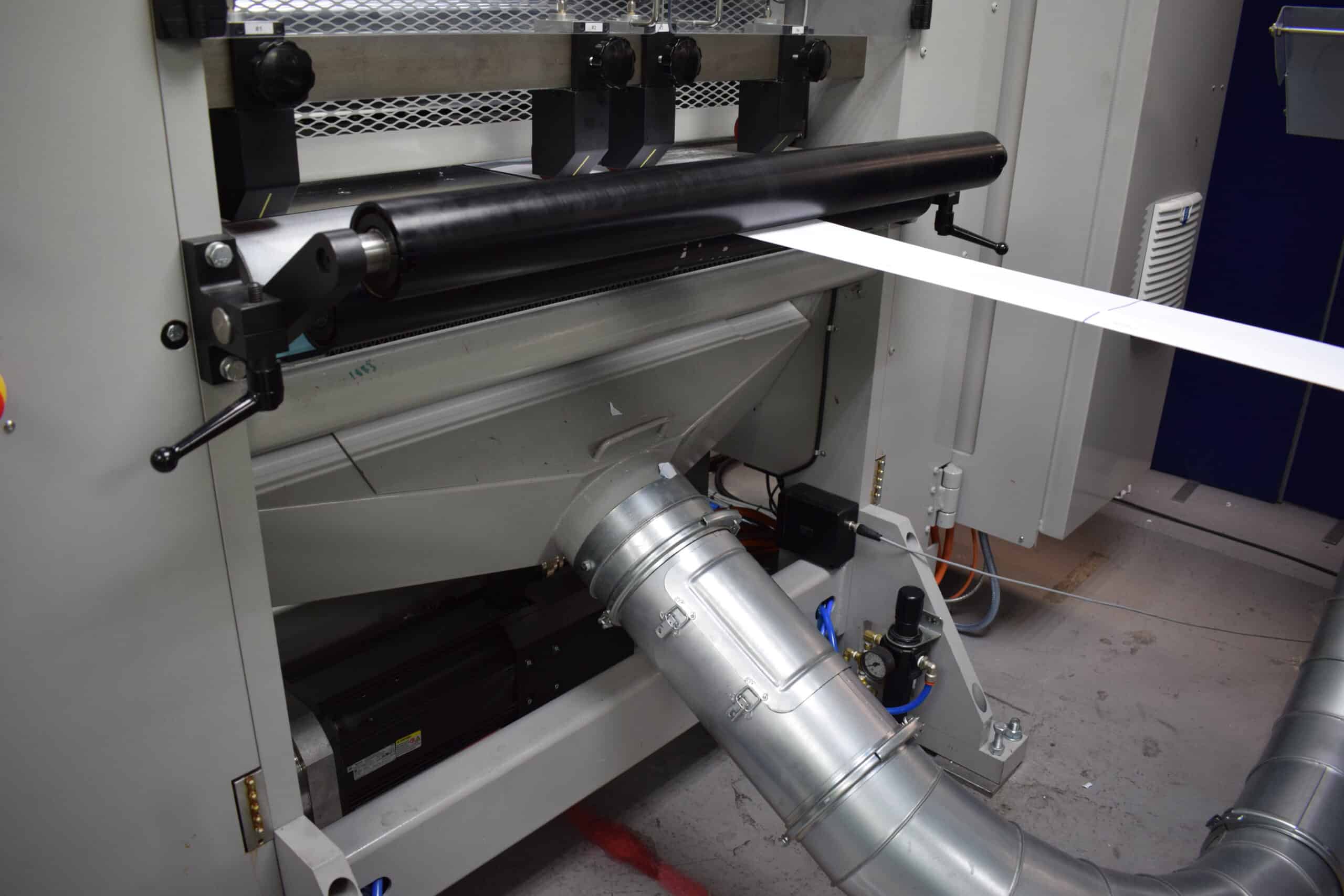

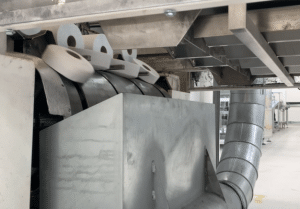

Due to the nature of the waste trim, (continuous edge trim as well as “chip out” waste) each line was fitted with a local chopper fan to break up the continuous trim, before being transported via a single common duct to the outside of the building and delivered to a twin compactor arrangement.

The hot air from each machine is exhausted via thermally lagged duct directly to atmosphere, as it does not contain any volatile organic compounds (VOC’s).

Over the past 25 years Impact Air Systems has worked alongside Go Inspire (formally as Graphic Inline/GI Solutions Group). Predominantly supplying waste extraction to all of their

printing and finishing processes. Enabling them to run at higher production speeds for longer periods of time, with little, if no operator interaction, due to the fully automated nature of Impact’s trim systems.

All of the collected waste is sent to a local waste paper merchant for recycling and reprocessing, further minimising production and transport costs.

Live Demonstrations. Proven Performance.

Send or bring a sample to our Resource Recovery Demonstration Facility and watch as we run it through our systems, showing you exactly how we can improve your process. Join us in person or online for a live, results-driven demonstration.

Learn MoreNeed technical services or spare parts?

Our nationwide service packages cover urgent repairs and scheduled maintenance. Skilled engineers respond quickly, supported by extensive spare parts stocks, ensuring your systems run at peak performance with minimal downtime and maximum reliability.

Learn More