Client Overview

ENVA is a leading environmental solutions provider operating across the UK and Ireland. Their Nottingham facility handles a wide range of waste streams—including household, commercial, and industrial dry recyclables—with a strong focus on maximising material recovery and landfill diversion.

The Challenge

The team at ENVA faced persistent issues with an ageing piece of separation equipment. The existing system was not only expensive to maintain but also struggled with efficiency, especially when handling light fibrous materials and glass from the residue line.

ENVA were after a reliable, cost-effective solution to handle lower volumes without sacrificing performance.

The Solution: Impact’s Compact ZAC400

Our newly developed Zigzag Air Classifier (the ZAC400) was the ideal replacement. Designed specifically for lower throughput applications, the ZAC400 uses the same proven air separation technology as its larger counterparts but in a compact package, making it perfectly suited to ENVA’s low-volume residue line.

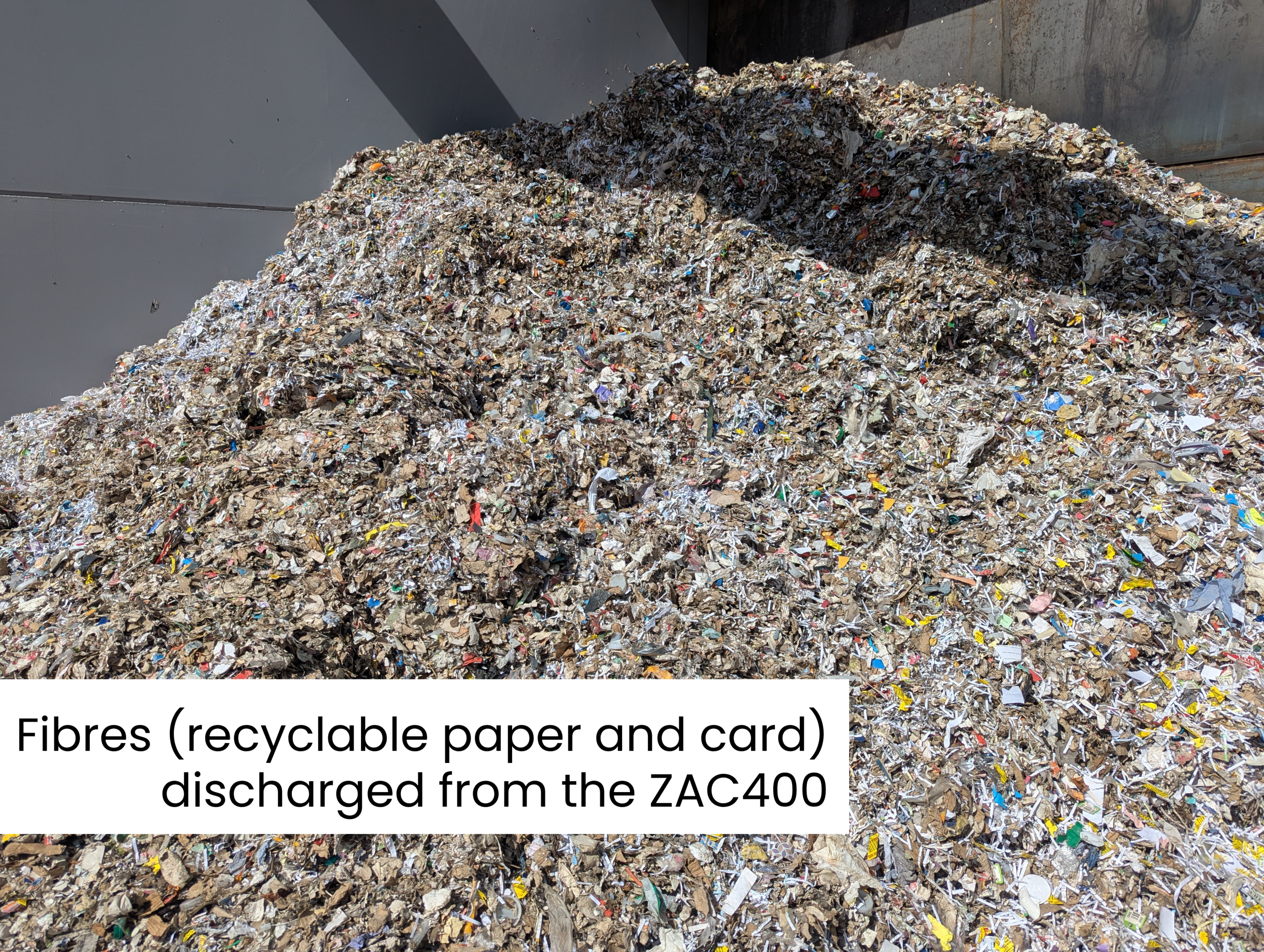

At this site, the ZAC400 is used to separate the glass and aggregate from the remaining recyclable fibres—like small pieces of paper and card—from the residue stream. This helps reduce landfill waste and allows more material to be recycled or turned into Solid Recovered Fuel (SRF).

Compact, Efficient Air Separation for Low-Volume Applications

The ZAC400 is used to separate lightweight materials from heavier particles by cascading the mixed-in feed material through an upwards-travelling air stream inside a zigzag-shaped enclosure.

Key Benefits:

- Produces high-quality output material

- Easy-access design reduces downtime

- Durable wear plates and rubber blades for long service life

- Simple to operate with a full-colour 10” HMI touchscreen interface

- Available in 800mm or 1200mm widths to suit different throughput needs

The Result:

Results: Improved Efficiency, Seamless Integration, and Ongoing Support

The installation of the ZAC400 has brought an immediate boost in operational efficiency at ENVA’s Nottingham site. Compared to the previous equipment, the new system requires significantly less maintenance and downtime, allowing ENVA to recover more recyclables from their residue line and maximise overall material recovery.

Before installation, our team conducted a detailed site survey to understand ENVA’s specific requirements. The ZAC400 was then tailored to suit their process and easily integrated into the existing line with minimal disruption, thanks to its compact design.

“The ZAC400 has been a positive addition to our Nottingham site,” says Paul Needham, Director at ENVA. “It’s much more efficient than the previous equipment, with less downtime and better glass recovery. The install was straightforward, and the support from Impact has been excellent.”

Beyond the Install: Ongoing Partnership

Alongside the ZAC400, ENVA benefits from continued technical support provided by our sister company, Impact Technical Services. This includes:

- A customised maintenance plan

- Fast-response servicing when needed

- Quick access to spare parts

This support helps keep the system running smoothly and efficiently, minimising downtime and ensuring consistent performance where it matters most.

The ZAC400 also joins a growing list of advanced solutions installed across ENVA’s sites, including our ZAC800 and Air Drum Separator (ADS900) at their Bourne facility.

To learn more about the full ZAC range and its capabilities, visit our ZAC product page.

Live Demonstrations. Proven Performance.

Send or bring a sample to our Resource Recovery Demonstration Facility and watch as we run it through our systems, showing you exactly how we can improve your process. Join us in person or online for a live, results-driven demonstration.

Learn MoreNeed technical services or spare parts?

Our nationwide service packages cover urgent repairs and scheduled maintenance. Skilled engineers respond quickly, supported by extensive spare parts stocks, ensuring your systems run at peak performance with minimal downtime and maximum reliability.

Learn More