Customer Success Story: Auria Solutions USA

Boosting Productivity and Recycling with Precision Air Conveyance

The Challenge:

Auria Solutions USA—one of the world’s largest suppliers of automotive acoustic and fibre-based products—needed a smarter, more efficient way to handle bulky carpet trim waste at their Fremont, Ohio facility. With a global headquarters in the UK and operations spanning the USA and Germany, Auria’s challenge was clear: improve productivity, streamline labour-intensive processes, and increase recycling—all without compromising product flow from their high-output, automated moulding lines and water-cutting cells.

A massive volume of skeletal trim waste measuring up to 2.8m x 2.0m needed to be pneumatically removed—whole, without any shredding—from production cells. The solution had to be fast, reliable, and designed to integrate seamlessly with existing operations.

The Solution: Engineered by Impact Air Systems

After proving feasibility through full-scale pneumatic conveyance trials, Auria selected Impact Air Systems as their project partner based on our proven engineering expertise and history of delivering high-performance systems in challenging manufacturing environments.

Working closely with Auria’s plant team, we developed a custom-engineered air conveyance and baling solution that:

- Reduced labour input, eliminating manual handling of large, awkward trim waste

- Maximised recovery, with material collected and baled for recycling into new Auria products

- Improved efficiency, freeing up production space and streamlining material flow

System Highlights:

- Custom collection troughs positioned between water cutting cells allowed operators to easily feed large-format trim waste into the pneumatic system, while maintaining safe, ergonomic workflow.

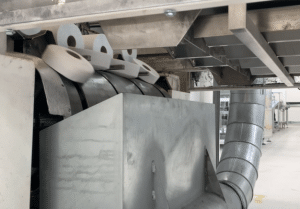

- Waste is transported via a precision-engineered ductwork extraction system to an Impact rotary separator, which discharges onto an incline belt conveyor feeding a twin-ram hydraulic baler.

- Baling integration was delivered through our long-standing U.S. partner, Recycling Equipment Inc. (REI), ensuring a seamless, turnkey solution.

- A smart sequencing system alternates collection between production cells to optimise energy usage, reduce footprint, and support future expansion.

- A summer/winter diverter ensures energy efficiency year-round by redirecting clean exhaust air: outside in summer, inside in winter for heat retention.

Real Results: Cleaner, Faster, More Sustainable Production

Today, the system is enabling Auria’s Fremont plant to handle bulky trim waste automatically, removing bottlenecks and reducing manual handling risks. The baled waste is shipped off-site for recycling and reintroduction into Auria’s own manufacturing process—closing the loop and aligning with the company’s sustainability targets.

Customer Testimonial:

“Impact Air Systems have delivered 100% on all aspects of the solution required. The project was on time, on budget, and met our expectations straight out of the box. Impact demonstrated professionalism and engineering excellence at every step. The solution is already proving its value and will deliver long-term benefit to our business.”

— Todd Hickmann, Plant Manager, Auria Solutions Fremont, Ohio

Why Leading Manufacturers Choose Impact

At Impact Air Systems, we don’t just build systems—we deliver tailored, future-ready solutions that improve performance, reduce waste, and help our clients stay competitive. From automotive to plastics, packaging to recycling, our systems are designed with operator safety, production efficiency, and environmental impact in mind.

Want to explore how we can help your facility increase throughput, recover more material, and reduce costs?

Call us today on +44 (0)116 244 8855 or email sales@impactairsystems.com.

Live Demonstrations. Proven Performance.

Send or bring a sample to our Resource Recovery Demonstration Facility and watch as we run it through our systems, showing you exactly how we can improve your process. Join us in person or online for a live, results-driven demonstration.

Learn MoreNeed technical services or spare parts?

Our nationwide service packages cover urgent repairs and scheduled maintenance. Skilled engineers respond quickly, supported by extensive spare parts stocks, ensuring your systems run at peak performance with minimal downtime and maximum reliability.

Learn More