Trim Extraction System Upgrade at Offset Print & Packaging

Client Overview

Offset Print & Packaging, based in Aylesford, UK, is a specialist in high-quality, bespoke printed cartons for a wide range of industries. With a strong reputation for innovation and precision, the company operates a busy production facility featuring multiple high-speed converting machines.

The Challenge

The existing trim extraction system was no longer fit for purpose. It struggled to keep up with the demands of modern production and was causing frequent breakdowns, blockages, and inefficiencies. As the company looked to expand its operations, a more robust and scalable solution was required—one capable of handling trim waste from both current and additional production lines.

The Solution

Offset Print & Packaging partnered with Impact Air Systems to design and install a brand-new trim extraction system. The comprehensive solution connects to:

- Two Bobst machines (extracting trim from the stripping edge and underside)

- One K&B Iberica (extracting stripped and blanked waste)

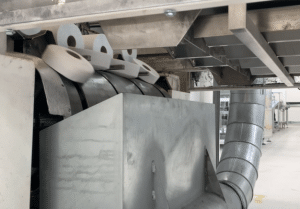

Trim waste is conveyed through a high-efficiency ductwork circuit to a chopper fan, material separator, rotary valve, and diverter drop chute, before being deposited into external compactors. The diverter chute enables continuous operation by alternating the output between compactors, eliminating downtime during changeovers.

Key Innovations

- Fan-assisted waste trucks on castors allow operators to easily reposition them for machine setup or maintenance—no tools required.

- A 300mm wide duct was installed to accommodate large sheet trim from the Bobst machines, ensuring smooth, blockage-free operation.

Results & Benefits

- Improved system reliability, reducing production downtime

- Increased compactor efficiency, resulting in fewer waste collections

- Enhanced sustainability by enabling more material to be recycled

- Reduced vehicle traffic and associated emissions from fewer waste collections

Client Feedback

“We are very pleased with all aspects—from design to installation to performance. The new system has significantly reduced downtime and allowed us to fill our compactors completely, resulting in fewer collections and more efficient recycling.”

– Vince Brearey, Managing Director, Offset Print & Packaging

Contact our technical sales team today to discuss your requirements.

Live Demonstrations. Proven Performance.

Send or bring a sample to our Resource Recovery Demonstration Facility and watch as we run it through our systems, showing you exactly how we can improve your process. Join us in person or online for a live, results-driven demonstration.

Learn MoreNeed technical services or spare parts?

Our nationwide service packages cover urgent repairs and scheduled maintenance. Skilled engineers respond quickly, supported by extensive spare parts stocks, ensuring your systems run at peak performance with minimal downtime and maximum reliability.

Learn More