Client Overview:

Sheard Packaging is one of the UK’s largest independent corrugated packaging manufacturers, known for delivering high-volume, high-quality solutions to some of the country’s biggest brands. With a strong focus on operational performance, Sheard partnered with us to upgrade their existing trim extraction system — aiming to increase capacity, improve reliability, and prepare for future growth.

The Challenge:

Over time, Sheard’s original trim extraction system had been expanded and modified to keep up with rising demand. However, the layout had become inefficient — particularly the placement of external fans, which were difficult to access for maintenance and inspection. This limited uptime, increased labour requirements, and constrained their ability to scale.

Our Solution:

We delivered a comprehensive upgrade that significantly enhanced performance, streamlined operations, and reduced ongoing maintenance demands.

Key features of our solution included:

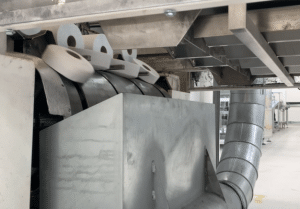

- High-Efficiency Trim Removal: A centralised extraction system takes production waste efficiently from multiple Göpfert Evolution, Emba and Asahi box-making machines and removes it to the baler room with improved flow, reducing manual handling and system blockages.

- Dual Baling System: We retained the existing baler and integrated a new unit, enabling Sheard to handle higher volumes, with less potential downtime, while reducing waste bulk and cutting transport costs.

- Optimised System Layout: External fans were rationalised and relocated to a more accessible position, dramatically improving maintenance access and minimising downtime.

- Energy Efficiency & Longevity: Conveying speeds were fine-tuned to optimise airflow, cut energy consumption, and reduce mechanical wear, along with the installation of a latest generation baler as the primary unit, significantly reducing energy consumption in the baling process — delivering ongoing cost savings.

- Centralised Smart Controls: A bespoke control panel now centralises system management, giving the client a clear dashboard, along with remote access to view system operation and faults, making start-up, shutdown, and troubleshooting faster and easier for operators.

- Future-Proof Design: The system is engineered with built-in flexibility to support future machinery and capacity upgrades without significant reinvestment.

The Outcome:

- Increased Capacity: The upgraded system now supports higher production volumes without bottlenecks or system strain.

- Reduced Operating Costs: Improved efficiency and energy use translate into real savings, while enhanced baling cuts transport and disposal costs.

- Minimal Downtime: Easier maintenance access and smarter controls result in faster servicing and improved uptime.

- Long-Term Flexibility: Designed to scale with Sheard’s growth, the system supports future expansion plans with minimal disruption.

Client Feedback:

“The team at Impact really understood our needs, delivering a system that supports long-term growth while improving performance and maintenance. The install was smooth and professional, with no disruption to production.” — Howard Elwin, Project Manager, Sheard Packaging

Impact’s Perspective:

“This project shows how collaborative engineering can drive both immediate performance improvements and long-term operational efficiency. The system is already helping Sheard’s teams work more efficiently and plan for the future.” — Darren Bayman, Sales Manager, Impact Air Systems

This project demonstrates how thoughtful engineering and future-ready system design can unlock real business value — improving productivity, reducing operational costs, and setting the stage for growth. For fast-paced manufacturing environments like Sheard Packaging, our tailored trim extraction solutions deliver measurable results from day one.

Live Demonstrations. Proven Performance.

Send or bring a sample to our Resource Recovery Demonstration Facility and watch as we run it through our systems, showing you exactly how we can improve your process. Join us in person or online for a live, results-driven demonstration.

Learn MoreNeed technical services or spare parts?

Our nationwide service packages cover urgent repairs and scheduled maintenance. Skilled engineers respond quickly, supported by extensive spare parts stocks, ensuring your systems run at peak performance with minimal downtime and maximum reliability.

Learn More