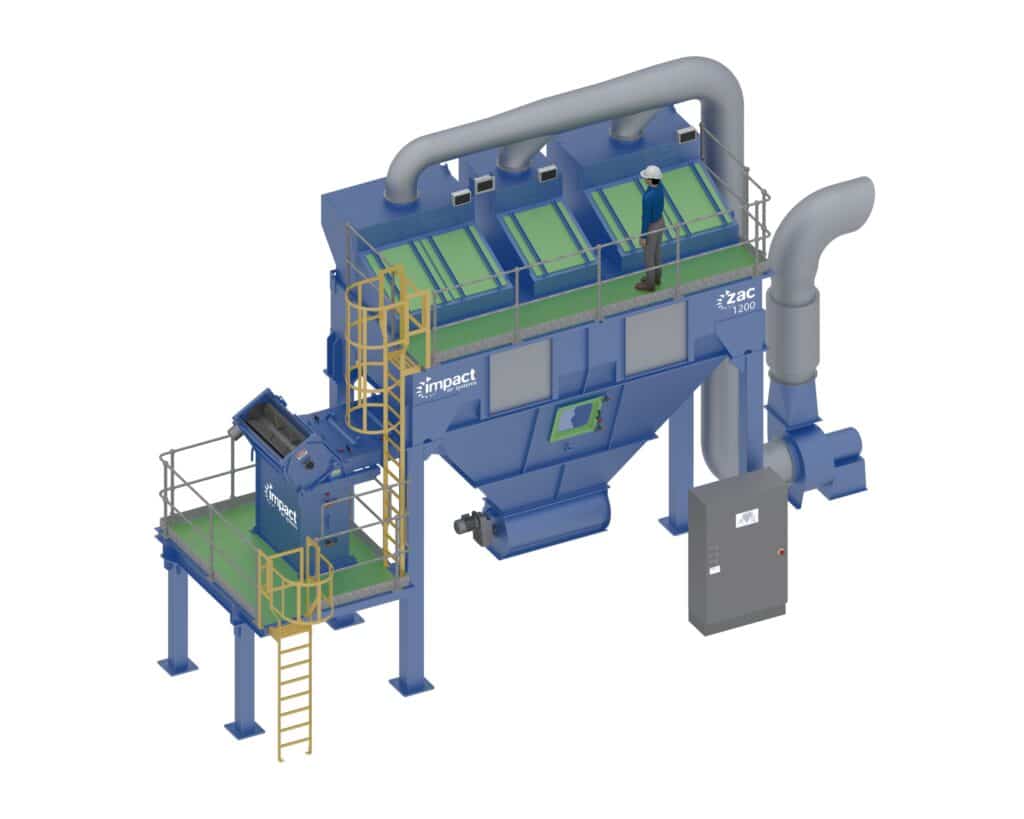

ZAC1200: Higher Throughput, Faster ROI, Same Exceptional Results

Due to growing demand for its industry-renowned Zigzag Air Classifier (ZAC), Impact Air Systems has introduced a higher-capacity model—the ZAC1200—developed in direct response to client requirements for increased throughput.

Building on the proven success of the ZAC800, the new ZAC1200 retains all the innovative features that made its predecessor so effective, but with a 50% increase in throughput capacity—handling up to 36m³/h compared to the 800’s 24m³/h. This makes it the ultimate solution for operators managing continuous and high-volume material streams.

Optimised for Tough Materials

The ZAC system is engineered for high-performance separation of SRF, glass, ceramics, and aggregates—particularly in glass-rich or highly abrasive sub-60mm waste streams. Designed for durability and minimal downtime, the unit features hardened chromium cast plates within the zigzag cascade enclosure to resist wear from sharp and abrasive materials.

A Profitable Recovery Solution

With increasing pressure on waste operators to extract the maximum value from their waste streams, the ZAC has become a must-have for those seeking reliable, high-yield material recovery. Impact’s Material Recovery Test Facility allows potential customers to trial their own waste samples and experience the impressive separation results first-hand—often leading directly to purchase.

“We process around 75,000 tons of C&D waste annually. Using the ZAC800, we’ve been able to effectively recover clean fractions of glass, stone, and ceramic from the sub-40mm stream for our recycled aggregate facility,” said one satisfied customer.

“Impact delivered exactly what they promised during testing. The machine paid for itself in just six months—and the ROI was so strong, we ordered another one.”

Book Your Material Demonstration

To schedule a visit to Impact’s Resource Recovery Demonstration Facility and see the ZAC in action for yourself, click here.