High-Performance Matrix Removal Systems

With over thirty years of industry expertise, Impact Air Systems is a leading provider of label matrix and edge trim extraction solutions. We’ve installed systems in facilities across the world—from the UK and Europe to the USA and Asia—helping manufacturers like CCL Industries and Avery Dennison increase productivity, minimise downtime, and improve operational efficiency.

Centralised Matrix Extraction Systems

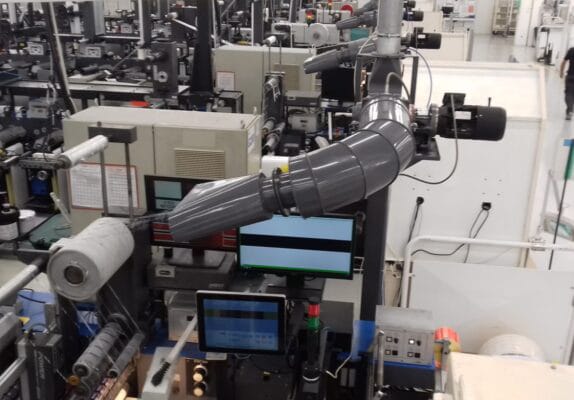

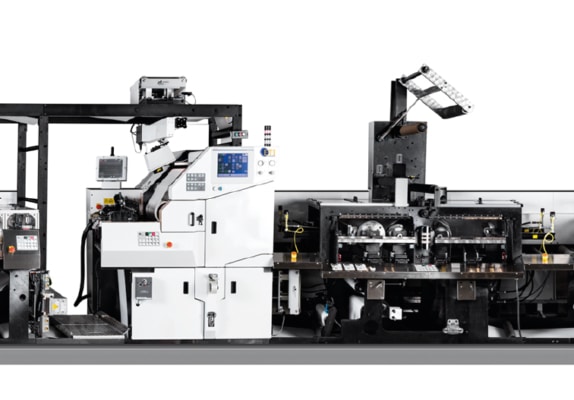

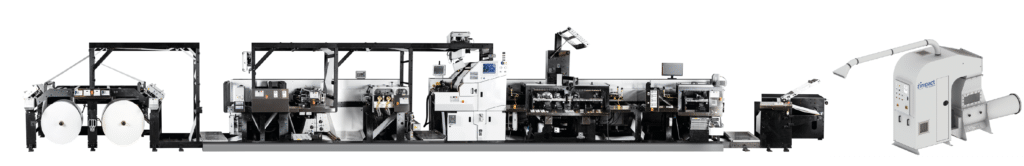

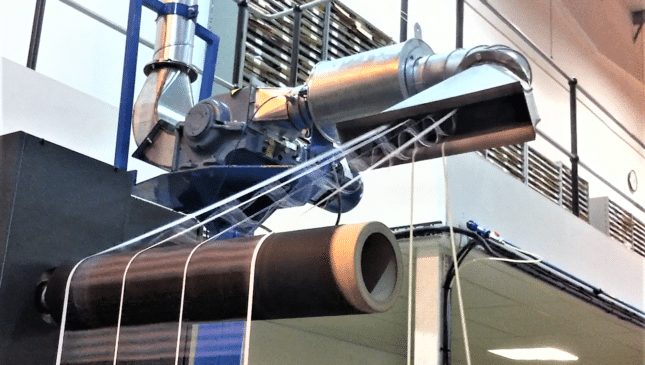

Our centralised matrix extraction systems are designed to seamlessly integrate with multiple narrow web presses (up to 500mm wide). Positioned on the non-operator side of the press, each unit features a precision trim cutter that chops the continuous matrix into small, manageable pieces. These are then transported via air ducting to a centralised collection point—eliminating the need for matrix rewinding and enabling longer, uninterrupted production runs.

Unmatched Reliability and Design Expertise

Engineered to deliver outstanding performance with minimal maintenance, our systems are built to withstand the toughest production demands. Our experienced design engineers and specialist installation team ensure every system is precisely configured, expertly installed, and tailored to your production space with a compact footprint. This is why clients return to Impact time and again, trusting our systems to keep their operations running smoothly.

Operational Benefits and Efficiency Gains

By removing sticky label matrix and edge trim efficiently, our solutions reduce manual handling, free up operator time, and create cleaner, safer production environments. The result is smoother workflows, increased output, and measurable cost savings—making our systems a valuable long-term investment.

Flexible Solution: Matrix Master

For smaller production setups or facilities requiring standalone equipment, the Matrix Master is the ideal packaged solution. Compact, flexible, and easy to install, it delivers the same high-performance matrix handling in a smaller format—perfect for short-run production or sites with limited space.

The Right System for You

Whether you’re running large-scale label manufacturing or small-batch operations, Impact Air Systems offers a solution to meet your specific needs. From fully integrated, centralised systems to compact standalone units, we help you take control of your waste and improve efficiency.

Our technical sales team are always on hand to discuss your project requirements. Contact us today.

Why Choose Us

-

Over 35 Years of Industry Expertise: Proven track record in air-based waste extraction, dust control and resource recovery solutions.

-

Engineered for Performance & Efficiency: Precision-designed systems that reduce downtime and improve production efficiency.

-

Leaders in Sustainable Recovery: Innovative technology that boosts recycling rates and cuts landfill waste.

-

Custom-Built Solutions: Every system is tailored to meet the unique demands of your facility and materials.

-

End-to-End Project Support: From concept and design to installation, commissioning, and ongoing maintenance and servicing.

-

Try Before You Buy: Test your material at our Resource Recovery Demonstration Facility.

-

Future-Proof Investment: Scalable systems designed to grow with your business and meet evolving regulations.

Benefits

- Handles All Matrix Types

Efficiently removes even the most challenging materials, including thin films and sticky waste streams. - Maximises Press Uptime

Reduces stoppages by eliminating tangled matrix and manual intervention. - Maintains Perfect Print Quality

Ensures stable register by removing matrix smoothly and continuously—off-press. - Boosts Production Speeds

Allows your presses to run faster with fewer limitations and waste-related interruptions. - Solves Tension Problems

Prevents rewind tension issues that often disrupt press performance and increase wear. - Eliminates On-Press Rewinding

No need for rewind spools—matrix is extracted directly and collected in a central system. - Enhances Workplace Cleanliness and Safety

Minimises manual handling, reduces clutter around the press, and promotes a safer, cleaner production environment.

Watch Our Systems in Action Here

For more videos visit our youtube channel

Label Matrix Removal Systems

Automated Trim and Matrix Removal

Label Matrix and Edge Trim Collection

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.