Smarter Separation

Fast Return On Investment

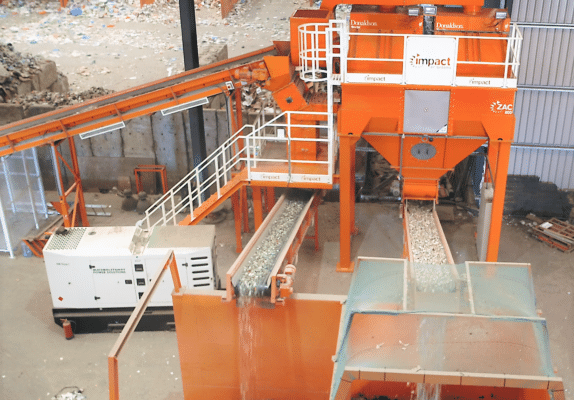

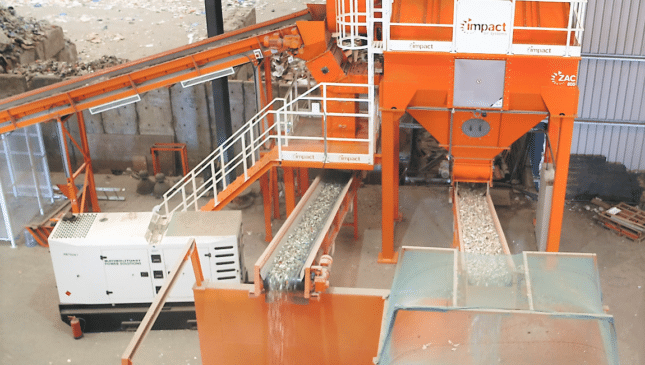

Impact recognises the industry requirements of ensuring a high-quality waste stream, so has further engineered the Zigzag Air Classifier (ZAC), a successful separation solution which greatly improves the separation of valuable recyclable materials while providing the operator with a low maintenance and hassle-free system. Throw in a super fast return on investment of as little as five months, and you’ve got the ultimate solution for your waste separation needs!

Long life, low maintenance

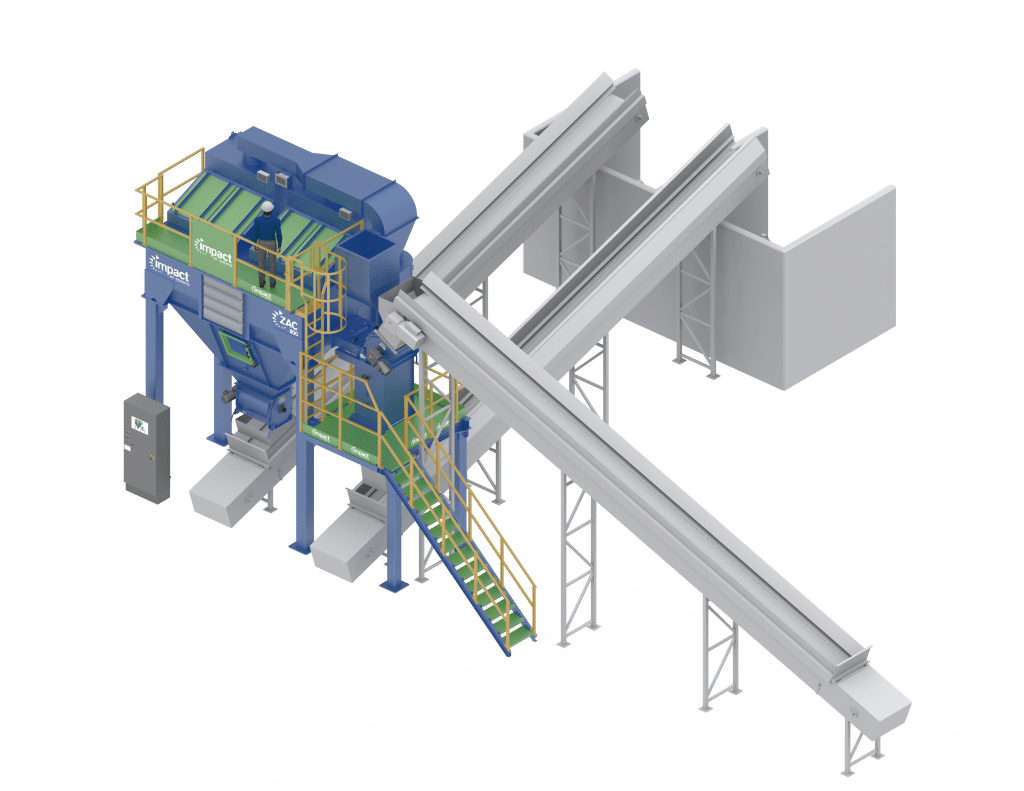

Combining our highly skilled in-house engineering team, 3D modelling software and working in conjunction with our carefully selected external supplier base, the ZAC boasts impressive resistance to abrasive materials, less moving parts and the very latest filtration technology, whilst maintaining its exceptional separation efficiency.

Utilising density separation by the power of air, the ZAC is specially engineered for processing of glass rich or highly abrasive sub 100mm material streams, constructed from carefully selected materials ensuring exceptional durability. The zigzag cascade enclosure includes hardened chromium cast plates to greatly reduce wear from glass.

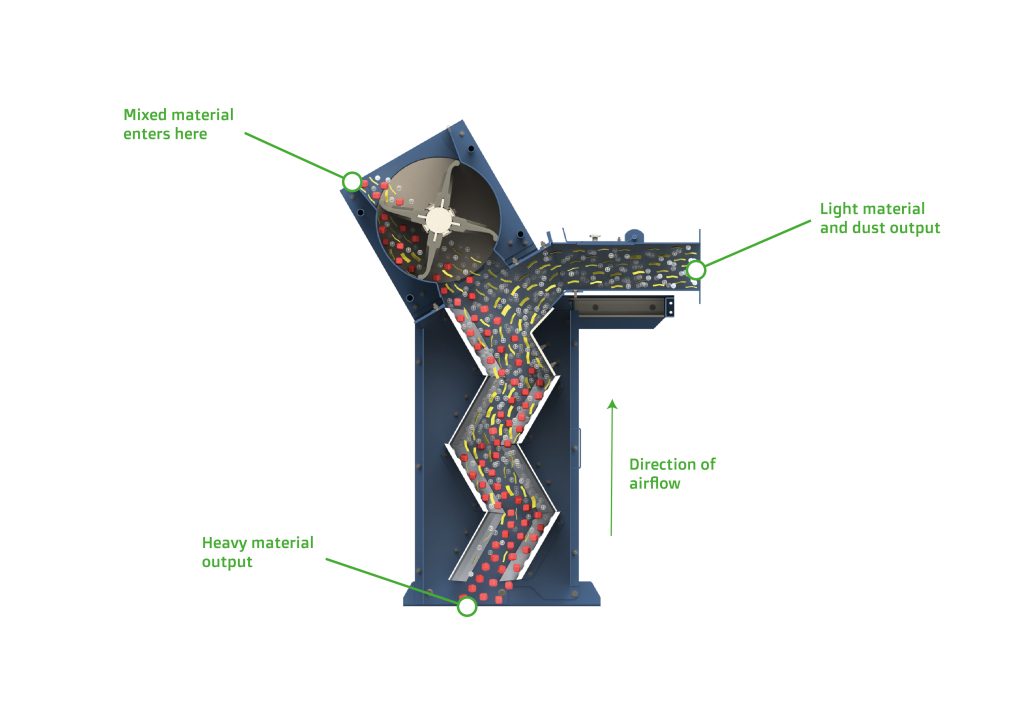

Advanced Separation Technology – How it works

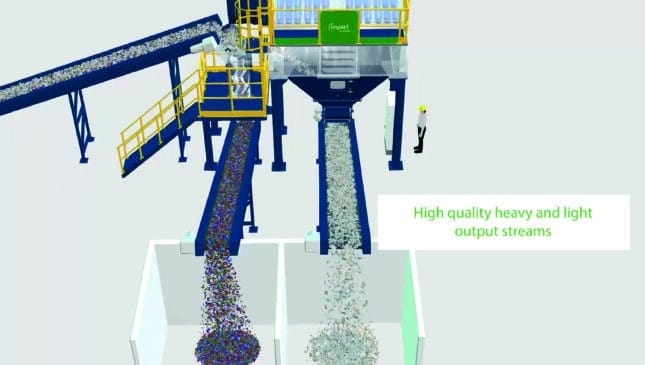

Zigzag material separation technology is used to separate light weight material particles from heavier particles by cascading the mixed in-feed material through an upwards travelling air stream inside a zigzag shaped enclosure.

An upwards travelling airstream collects the lightweight material particles, allowing separation or grading of feedstock. Heavier material particles are not affected by the airstream and discharge at the bottom of the zigzag enclosure.

Applications

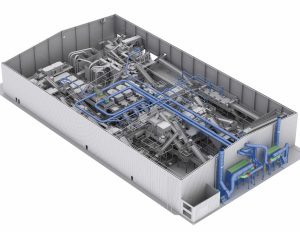

The Zigzag Air Classification technology is ideally suited to low moisture, free flowing, consistently sized material particles up to approximately 60mm in size, where there is a noticeable difference in the product density or weight (i.e. separation of lightweight paper, film, dust and plastic from heavier stone, glass or metal). Recent installations have included WEEE and SRF recovery, Commercial & Industrial (C&I) and SRF recovery, MRF fines and glass, MSW, DMR and finished SRF.

Zigzag Separation Alternatives

We offer a range of alternative Zigzag Separation Solutions tailored to your specific needs. Contact our Technical Sales Team to discuss your application, and we’ll recommend the most effective system for your operation – visit our Zigzag Separation System page here.

Try Before You Buy

Get in touch with our expert technical sales team to discuss your project needs and see our solutions in action. Book a visit to our Resource Recovery Demonstration Facility and ‘try before you buy’—using your own material. Discover the results for yourself!

Why Choose Us

-

Over 35 Years of Industry Expertise: Proven track record in air-based waste extraction, dust control and resource recovery solutions.

-

Engineered for Performance & Efficiency: Precision-designed systems that reduce downtime and improve production efficiency.

-

Leaders in Sustainable Recovery: Innovative technology that boosts recycling rates and cuts landfill waste.

-

Custom-Built Solutions: Every system is tailored to meet the unique demands of your facility and materials.

-

End-to-End Project Support: From concept and design to installation, commissioning, and ongoing maintenance and servicing.

-

Try Before You Buy: Test your material at our Resource Recovery Demonstration Facility.

-

Future-Proof Investment: Scalable systems designed to grow with your business and meet evolving regulations.

Benefits

-

High-Purity Output: Achieve cleaner, higher-value material streams ready for resale or reuse.

-

Rapid ROI: Generate a return on investment in as little as 5 months through material recovery and cost savings.

-

Boosted Revenue: Recover more recyclable content and convert waste into profit.

-

Lower Disposal Costs: Cut landfill volumes and reduce your landfill tax liabilities.

-

Minimal Maintenance: Engineered for long-term reliability with fewer moving parts and easy servicing.

-

Built to Last: Tough, abrasion-resistant components designed for demanding materials like glass and metals.

-

Flexible Sizing: Available in 400mm, 800mm or 1200mm zigzag widths to match your throughput and application needs.

Watch Our Systems in Action Here

For more videos visit our youtube channel

How it works...

Glass and SRF Recovery Solution

Glass and RDF Recovery

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.