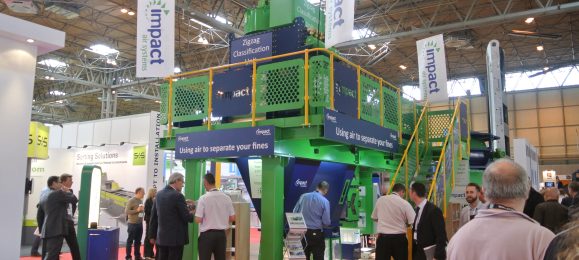

In a crowded industry with many solutions claiming to separate and recover valuable materials from the waste stream, Impact’s Zigzag Air Classifier (ZAC) stands head and shoulders above the rest thanks to its unrivalled ability to recover a diverse range of materials at continually high throughput rates.

Maximum recovery

With increased pressure on waste management companies to ensure maximum recovery of valuable materials from the waste stream, along with the benefit of turning it into a valuable commodity, many have been lining up to bring their material sample to Impact’s materials recovery test facility, where they can run a sizeable sample through the ZAC to see the recovery results before they invest. The reasonable price tag, innovative engineering, small footprint, after sales support and, of course, the recovery results, equates to a high percentage of the trials ending in a sale.

Utilising density separation by the power of air, Impact’s ZAC is specially engineered for processing of glass rich or highly abrasive sub 100mm material streams, constructed from carefully selected materials ensuring exceptional durability. The Zigzag cascade enclosure includes hardened chromium cast plates to greatly reduce wear from glass and other abrasive materials. The ZAC was originally developed for aggregate rich material streams and has been engineered with durability and ease of maintenance and cleaning in mind.

How it works

Zigzag material separation technology is used to separate light weight material particles from heavier particles by cascading the mixed in-feed material through an upwards travelling air stream inside a zigzag shaped enclosure.

An upwards travelling airstream collects the lightweight material particles, allowing separation or grading of feedstock. Heavier material particles are not affected by the airstream and discharge at the bottom of the zigzag enclosure.

The zigzag air classification technology is ideally suited to low moisture, free flowing, consistently sized material particles up to approximately 60mm in size, where there is a noticeable difference in the product density or weight (i.e. separation of lightweight paper, film, dust and plastic from heavier stone, glass or metal).

Applications

The ZAC can be found recovering materials from C&I waste streams, C&D, trommel fines, gypsum and MRF streams. A waste processor in Hartlepool, chose the ZAC800 to refine the SRF material it produces, ensuring it is of the highest quality possible for future use as an alternative to fossil fuel. With a throughput of eight tonnes per hour, the waste processor required a system that could easily manage the high throughput and bulk density of approximately 220 kgs/m³, of which the ZAC800 is more than capable.

Impact has also recently installed a system at a waste management company in Lincolnshire, who required a double ZAC1200, capable of processing 14 tonnes per hour of SRF material by removing unwanted stone, glass, and aggregates from the final product.

Impressive Installations

Another ZAC800 installation has recently taken place at a waste site of a C&D company. The material streams produced by this waste were not able to be recycled without processing and refinement. Impact’s ZAC800 removes the aggregate material, dense plastics, metals, and glass, leaving the fine SRF material of paper, fibre, and thin plastic film.

Plasterboard gypsum and paper separation has also been a popular requirement, of which the ZAC800 performs flawlessly. The clean gypsum material streams are impressive, while all paper residue is removed, leaving a high-quality product.

We ordered two!

One customer commented on its ZAC installation “We process around 75,000 tons of construction and demolition waste and with the ZAC800 we are able to process the sub 40mm fraction and very effectively achieve a mix of clean glass, stone and ceramic that can be used in our recycled aggregate facility. Investing in Impact’s ZAC800 was an easy decision for me, Impact carried out a detailed trial on our material and the results that were promised, have now come to fruition. It can process waste streams at a high hourly throughput with material recovery results that are very impressive. The value in the cleaned glass and stone stream and Solid Recovered Fuel (SRF) stream will pay for the machine within the first 6 months of operation. The payback on this system has been so good, we’ve ordered another one!”

Nick Ball, managing director of Impact Air Systems said “The ZAC800 rarely fails to impress with its separation ability. We carry out material trials every week which mostly result in a sale. The fast ROI really is the icing on the cake and is the reason the ZAC800 can be found in a fast-growing number of waste facilities all over the world. We invite anyone to bring a sample of their material along and see the results for themselves!”

To book an appointment at Impact’s test facility and to see Impact’s ZAC in action, visit www.impactairsystems.com.

Impact Air Systems, the world’s leading air-based technology provider for the environmental, waste, recycling, and resource management industry, announces they are to exhibit their innovations at three major trade shows to cover the USA...

The recycling facility is capable of processing 144K tons of material a year and will contribute to the circular economy with its state-of-the-art features. The Impact Airlift is an integral component at this facility,...