Streamlined Waste Management for Label Production

Maximise Efficiency with the Matrix Master Unit

The Impact Matrix Master offers a flexible localised extraction solution for typical label and self-adhesive products without needing to install a central waste system.

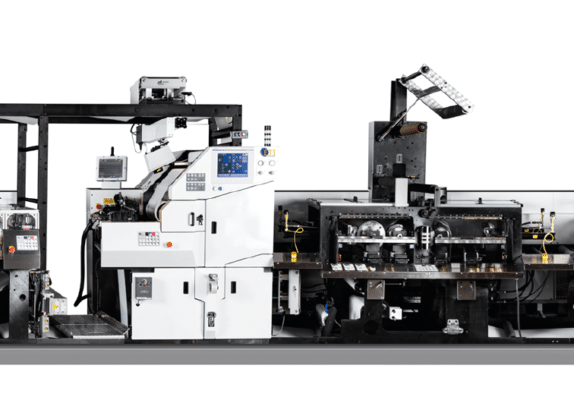

Revolutionise your label production with the Matrix Master unit, engineered for seamless integration with our highly versatile precision trim cutter. Designed to effortlessly manage sticky self-adhesive matrix, lattice waste, and edge trim, this compact powerhouse streamlines your entire waste handling process. Housed in a sleek acoustic casing, the Matrix Master combines a precision trim cutter, waste handling fan, material separator, and a disposable exhaust air dust filter for a truly self-contained solution.

Non-Stick Technology for Unmatched Performance

Position the Matrix Master next to your press and watch it effortlessly collect waste through a series of ductwork, transporting it directly to a convenient polythene bag for easy disposal. Our high-performance precision trim cutter efficiently trims continuous matrix waste, while the advanced plasma non-stick coating ensures that adhesive matrix won’t stick to the internal surfaces, maintaining smooth operation and minimising downtime.

Tailored Solutions for Your Needs

Take it a step further with our optional waste screw compactor unit, which compresses waste into a sausage-shaped bag for simple, uninterrupted disposal. The Archimedes screw compactor ensures you can keep your production line moving without having to stop and replace full bags. Plus, the Matrix Master comes with an integrated control system and a plug-and-play flying lead, making setup and operation incredibly easy.

Proudly manufactured in the UK, the Matrix Master, along with all our solutions, is supported by our fast-access spare parts and expert service. Get ready to boost productivity and waste management efficiency like never before! Contact our team today.

Why Choose Us

-

Over 35 Years of Industry Expertise: Proven track record in air-based waste extraction, dust control and resource recovery solutions.

-

Engineered for Performance & Efficiency: Precision-designed systems that reduce downtime and improve production efficiency.

-

Leaders in Sustainable Recovery: Innovative technology that boosts recycling rates and cuts landfill waste.

-

Custom-Built Solutions: Every system is tailored to meet the unique demands of your facility and materials.

-

End-to-End Project Support: From concept and design to installation, commissioning, and ongoing maintenance and servicing.

-

Try Before You Buy: Test your material at our Resource Recovery Demonstration Facility.

-

Future-Proof Investment: Scalable systems designed to grow with your business and meet evolving regulations.

Benefits

-

No More Rewinding on Press: Removes the hassle of rewinding waste matrix and edge trims directly on the press. The Matrix Master streamlines your entire waste management process.

-

Versatile Applications: Ideal for a wide range of materials, including PSA label stock, laminated trim, and film. No matter the material, the Matrix Master handles it with ease.

-

High-Speed Performance: Supports web widths of up to 500mm and press speeds of up to 150 meters per minute, ensuring maximum productivity without compromising on efficiency.

-

Solve Complex Waste Issues: Effortlessly eliminate production challenges caused by awkward or irregular waste matrix patterns that typically prevent smooth rewinding on press.

-

Eliminate Manual Handling: Say goodbye to the traditional headaches of handling large spools of waste matrix—no more manual handling, reducing risks and improving safety.

-

Mobility and Flexibility: The Matrix Master is a mobile unit, making it easy to move between presses as needed to maximise operational flexibility.

-

Quiet, Efficient Operation: Enjoy a quiet and highly efficient operation, ensuring your workflow stays smooth and uninterrupted.

Watch Our Systems in Action Here

For more videos visit our youtube channel

Label Matrix Master Removal Solution

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.