Extraction Excellence

At Impact Air Systems, we’ve been at the forefront of production waste and trim extraction since the 1980s—delivering reliable, high-performance solutions that help manufacturers streamline processes, reduce manual labour, and unlock hidden value from waste.

Maximise Productivity. Minimise Waste. Increase Profit.

From paper, carton board, corrugated board, foil, film, sticky labels, tissue and even can scrap – we design, engineer and install bespoke industrial waste extraction systems that keep your operation running cleaner, faster and more efficiently.

Whether you operate in printing, packaging, labelling or beverage can manufacturing, our high-performance waste extraction solutions are trusted by industry leaders worldwide to remove edge trims, off-cuts and production waste quickly and efficiently — helping you boost throughput and improve recycling performance.

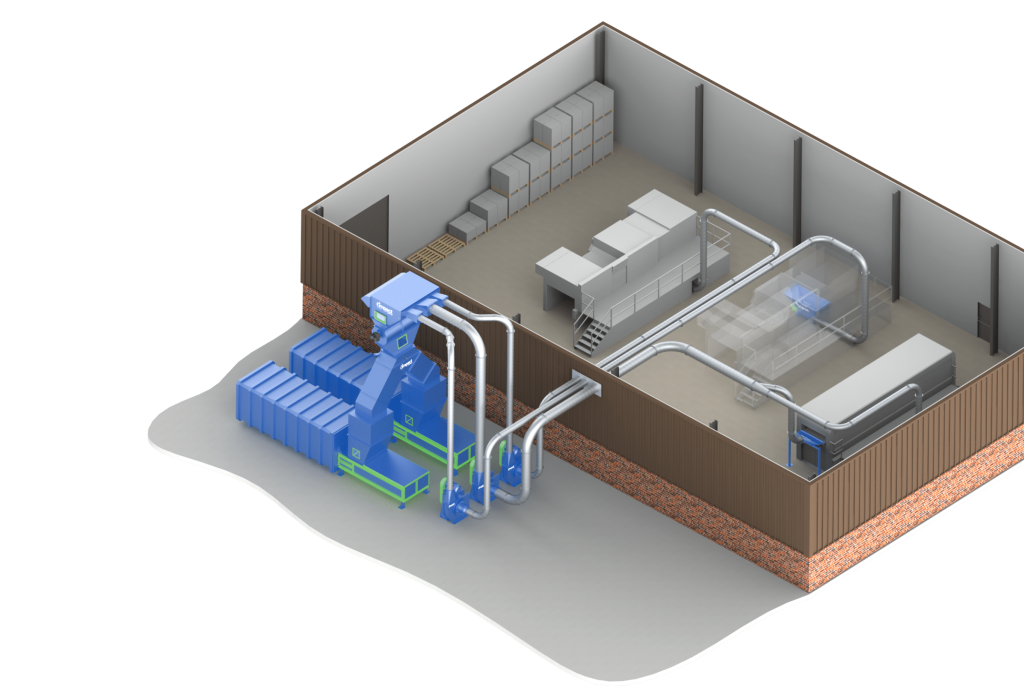

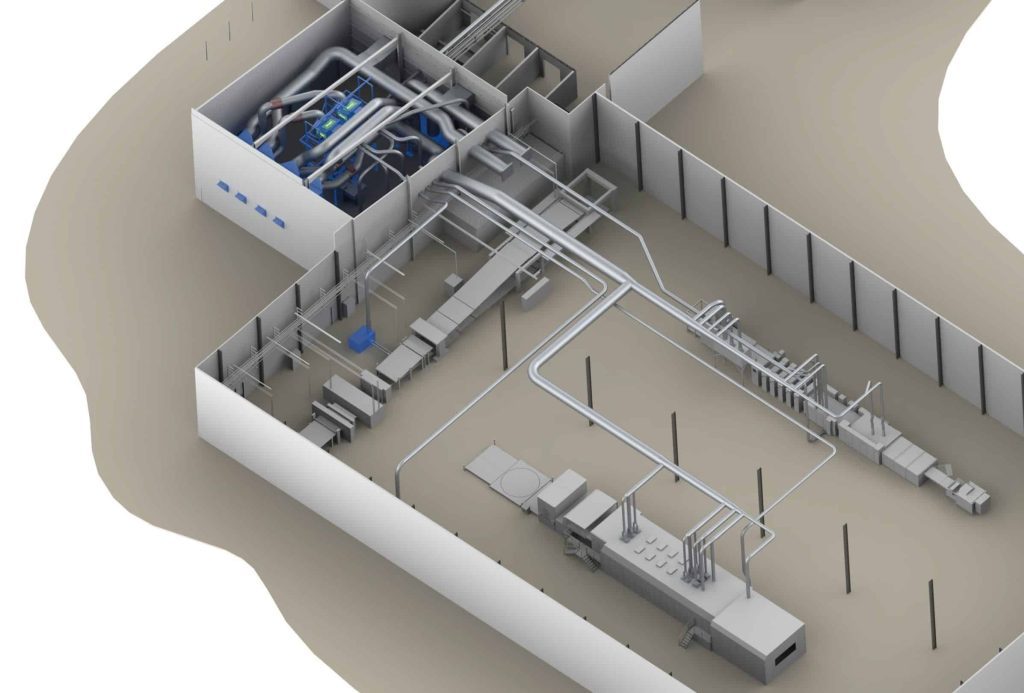

We deliver everything from fully integrated, turnkey extraction systems to compact standalone units — each engineered to eliminate bottlenecks, reduce downtime and recover value from recyclable materials.

Engineered for High-Speed Trim Removal

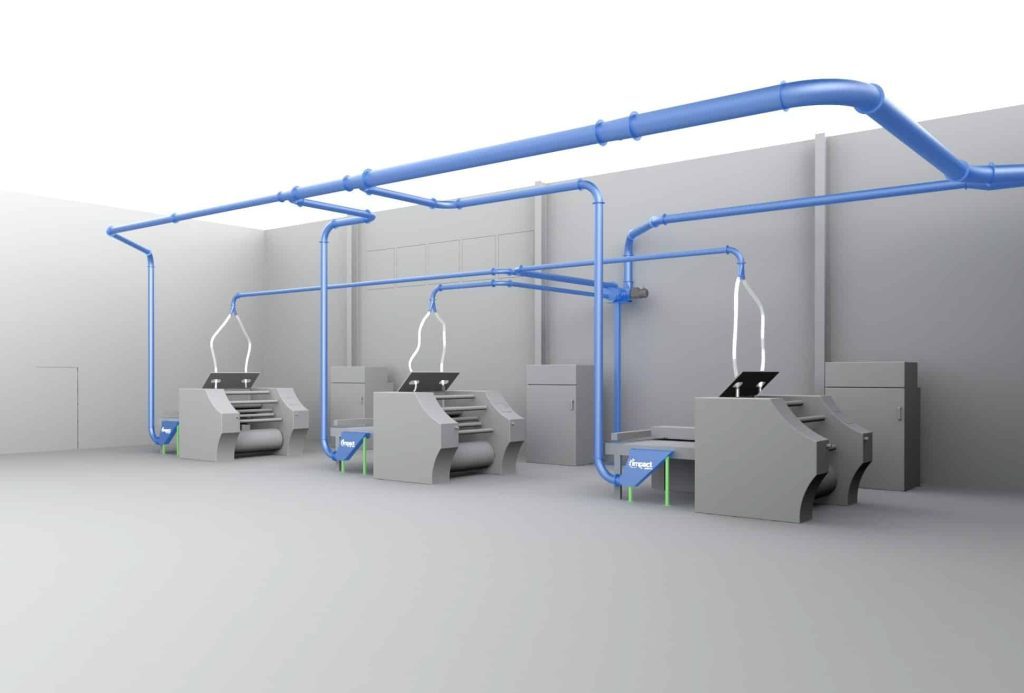

Handling high-speed slitting or wide, heavy-duty trims? No problem. Our industrial trim extraction systems are designed to manage the toughest waste removal challenges — including edge trims travelling at up to 1,500 metres per minute — with exceptional precision, reliability and power.

Precision Engineering for Demanding Applications

When processing high-speed or heavyweight materials such as corrugated board and laminated edge trims, equipment placement and specification are critical.

That’s why every system we produce is built with durability, performance and efficiency at its core.

We partner with leading OEMs and blue-chip manufacturers across multiple sectors to deliver proven, high-performance waste extraction solutions time and again.

At the heart of every system lies our heavy-duty chopper fan, purpose-built to break down continuous trims into manageable pieces — ensuring smooth material flow, reliable waste handling and minimal production disruption.

Smarter Waste Handling for a Sustainable Future

Our systems don’t just remove waste — they optimise production, reduce environmental impact and support your sustainability objectives.

From improved energy efficiency to increased material recovery, our industrial waste extraction systems help manufacturers achieve cleaner, more productive and more profitable operations.

Let us show you how efficient waste extraction can transform productivity, profitability and sustainability across your entire production line.

Trusted Across Every Industry

Our bespoke solutions are engineered to perform in:

- Printing and converting

- Packaging and labelling

- Corrugated board production

- Tissue and hygiene manufacturing

- Beverage can and metal packaging

- Film, foil and flexible materials

Wherever waste is generated, we provide the engineering expertise and system reliability you can depend on.

Let us show you how efficient waste extraction can transform your productivity and sustainability goals.

Why Choose Us

-

Over 35 Years of Industry Expertise: Proven track record in air-based waste extraction, dust control and resource recovery solutions.

-

Engineered for Performance & Efficiency: Precision-designed systems that reduce downtime and improve production efficiency.

-

Leaders in Sustainable Recovery: Innovative technology that boosts recycling rates and cuts landfill waste.

-

Custom-Built Solutions: Every system is tailored to meet the unique demands of your facility and materials.

-

End-to-End Project Support: From concept and design to installation, commissioning, and ongoing maintenance and servicing.

-

Try Before You Buy: Test your material at our Resource Recovery Demonstration Facility.

-

Future-Proof Investment: Scalable systems designed to grow with your business and meet evolving regulations.

Benefits

-

Increase Output Efficiency

Keep production lines running at full speed—no jams, no downtime. -

Minimise Manual Handling

Automated extraction systems reduce labour requirements and safety risks. -

Maximise Recycling & Recovery

Clean, separated trim makes recycling easy and valuable. -

Boost Environmental Credentials

Meet sustainability targets and reduce your carbon footprint. -

Tailored to Your Needs

Full turnkey systems or standalone solutions, custom-built to your process.

Watch Our Systems in Action Here

For more videos visit our youtube channel

Trim Removal from Digital Print

Aluminium Can Scrap Removal

Continuous Edge Trim Removal

Print Trim Extraction Solutions

Carton Board Matrix Removal

Aluminium Can Scrap Removal

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.