Zigzag Separation – Smarter Material Cleaning

In today’s recycling industry, waste operators face ongoing pressure to reduce contamination, maximise throughput, and increase the quality—and therefore the value—of recovered materials. Impact’s Zigzag Separation System offers a game-changing solution that boosts performance without adding complexity.

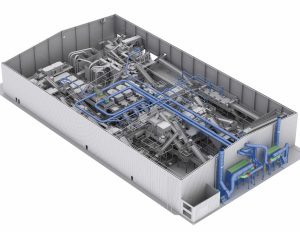

Engineered with flexibility in mind, the system can be easily integrated into existing recycling lines and is uniquely capable of incorporating material transfer—making it ideal for sites with evolving layouts or mixed material handling requirements. Whether you’re upgrading a single line or optimising an entire facility, the Zigzag Separator adapts seamlessly to your operation, delivering clean, high-value output with minimal disruption.

Already a staple in Material Recycling Facilities (MRFs) and used across the broader recycling and recovery sector, our Zigzag Separation System delivers highly effective, air-based separation for a wide variety of material types. From lightweight plastic films and fibre to rigid plastic flake, WEEE components, and even specialist materials like rubber crumb from artificial turf, the Zigzag Separator helps operators turn mixed, contaminated input into clean, saleable fractions.

For the waste operator, the payoff is immediate. By integrating a Zigzag Separation System into your process—typically at a conveyor junction—you can dramatically reduce the volume of rejected or downgraded materials caused by light contaminants. That means fewer loads to landfill, lower disposal costs, and more value recovered from every tonne of material processed. Additionally, cleaner output increases compliance with end-market requirements.

Flexible Density Separation – How does it work?

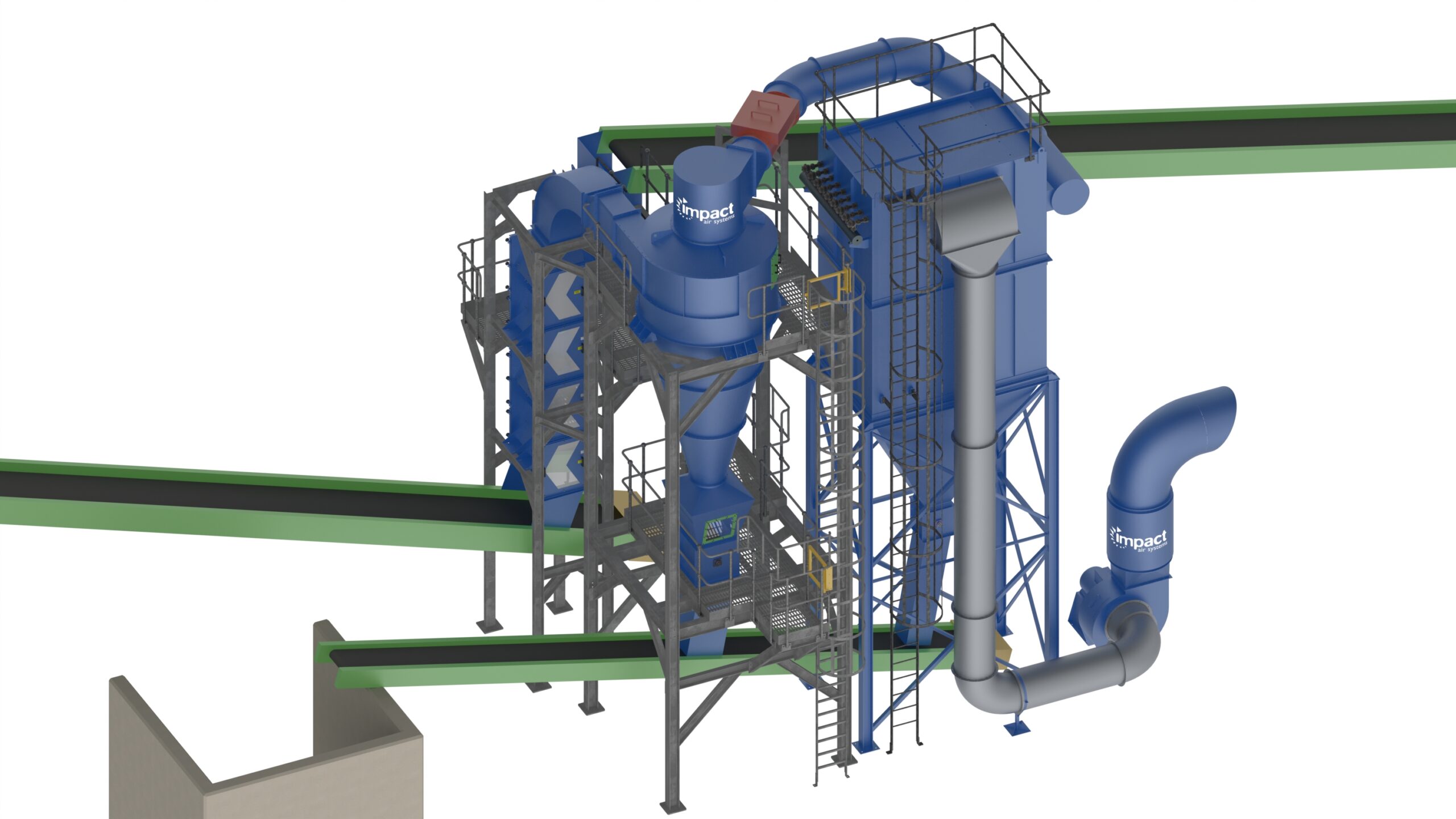

As contaminated feedstock enters the Zigzag Separation System via a variable-speed rotary valve, it cascades through a vertical channel equipped with angled baffles. A custom calibrated upward airflow moves through the system, lifting lightweight debris such as dust, films, and fibres away from heavier materials.

Unlike manual picking or basic screening methods, the Impact Zigzag Separation System provides consistent, high-throughput performance—effectively separating material without slowing down production. Operators benefit from greater control and flexibility, thanks to adjustable airflow and system configurations that can be fine-tuned for specific material profiles and contamination levels.

And because the system can be scaled to suit different volumes and facility layouts, it’s an ideal solution whether you’re upgrading a small line or expanding a large-scale MRF. Installation is straightforward, integration is seamless, and the return on investment is both measurable and rapid.

Real-World Results, Proven Performance

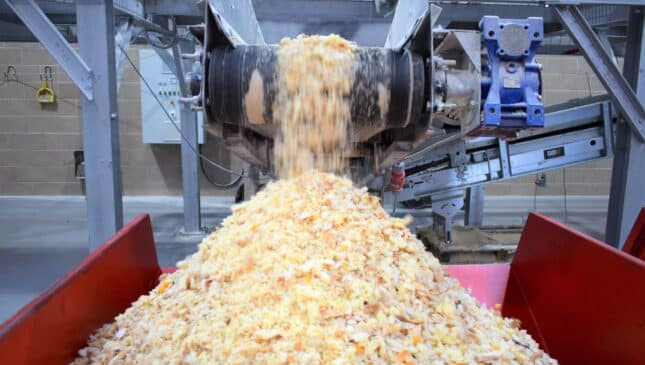

In our in-house Resource Recovery Demonstration Facility and across operational sites, our Zigzag Separation System has delivered standout results in a wide range of scenarios. From separating glass and fibre, rigid plastic flake and fibre, plasterboard gypsum, shredded food packaging and coffee pods, to tackling complex waste streams like circuit boards, plastic CD cases, and shredded car dashboards, operators have seen clear results.

By recovering more recycable material and reducing the burden on downstream sorting, the Zigzag Separator frees up labour, improves plant efficiency, and unlocks more value in your waste stream. And because it reduces contamination early in the process, it also helps prevent costly equipment wear and avoids downtime caused by blockages or material build-up.

Let’s Talk About Your Waste Stream

If you’re looking to reduce operating costs, improve bale purity, and get more from every load, our Zigzag Separation System is ready to make a measurable impact. Whether you process dry mixed recyclables, RDF/SRF, plastics, metals, or fines, we’ll help you implement a tailored solution that fits your process and delivers long-term value.

We offer a range of Zigzag Separation solutions, including our Zigzag Air Classifier for more abrasive materials at varying throughputs, so to find the best solutions that meets your requirements, contact our Technical Sales Team for more information.

Call us on 0116 244 8855 or email sales@impactairsystems.com.

Partner with Impact—and see how smarter air separation leads to cleaner outputs, higher profits, and less waste.

Benefits

- Ideally suited to 5-60mm material fraction

- Dosing controlled via variable speed rotary valve

- Fully adjustable air flow controls both via manual dampers and electronic fan speed controls

- Outstanding results to significantly improve the cleanliness of material stream

- Minimal loss of valuable recyclable material during cleaning operation

- High material throughput capabilities

- Suitable for a wide range of material applications, such as rigid plastics / plastic containers recycling process

- Used in conjunction with the Impact range of material separators and dust filtration

Watch Our Systems in Action Here

For more videos visit our youtube channel

Glass and RDF Recovery

Bread & Packaging Separation

Glass & Fibre Recovery Solution

Fridge Recycling - Metal Recovery

Plastic Flake and Fibre Separation

Plasterboard - Gypsum Recovery

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.