Simpler Recycling

Reshaping how recycling is collected and processed across the UK will require operators to re-assess their current waste operations — incorporating or adjusting separation and sorting processes to enhance efficiency and help facilities meet new regulatory standards.

quality waste streams

Simpler Recycling –

What it means

The UK Government’s Simpler Recycling reforms (England) aim to make recycling easier and more consistent by standardising the materials collected from every household and business by March 2027. This means that wherever people live or work, the same core set of materials — such as paper, card, glass, metal, plastics, food waste and later flexible plastic film — will be collected in a consistent way.

The reforms are designed to eliminate local variation, reducing confusion for residents and businesses about what can or can’t be recycled.

Key Changes

Standardised recycling collections

Every local authority and business must collect the same core set of materials:

Paper & card, plastic, metal, glass, food waste — and by 2027, flexible plastic film.

Expanded coverage & consistency

All households, businesses, and organisations (including micro-firms) must separate recyclables into these standard streams.

Weekly food waste collections become mandatory for households.

Reduced contamination & improved quality

Consistent bin systems will reduce mixed-waste confusion and contamination, increasing demand for efficient pre-sorting and handling technologies.

Implementation timeline

- 2025: Larger businesses (10+ employees) must comply

- 2026: Weekly food waste and core recyclables collected from all homes

- 2027: Plastic film added; full rollout across England

Waste separation and dust control

Resource Recovery Solutions from Impact

Flexible Film Capture Solutions

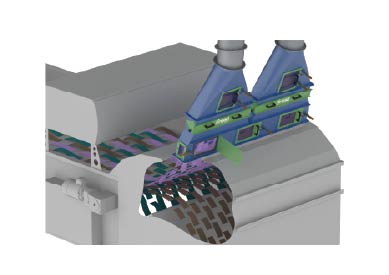

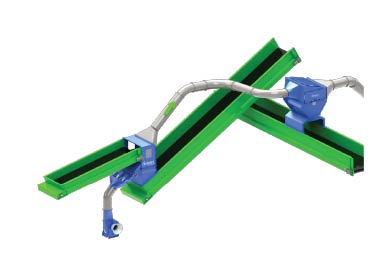

The inclusion of plastic film recycling aligns directly with our FilmLift and FilmVac systems — proven technologies for capturing lightweight, flexible film and plastic packaging from conveyors and sorting lines.

Efficiency & Contamination Control

Our air-based separation and capture systems support cleaner recyclable streams and more efficient processing — matching the directive’s emphasis on reducing contamination and improving recycling quality.

Plant Upgrades & Retrofit Support

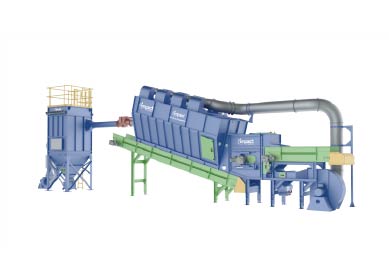

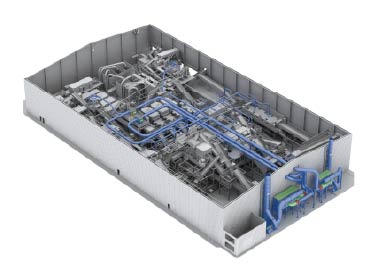

As MRFs, PRFs, and waste-management operators adapt to handle new materials and larger volumes, Impact can provide turnkey retrofit solutions and process improvements for air extraction, film handling, and dust/particulate control.

Partnering for Compliance & Performance

We help recyclers future-proof their systems ahead of 2027 — ensuring they meet new collection requirements while improving safety, cleanliness, and recovery efficiency.

We’re proud to work with many clients in this industry…

Industry Leader

Why choose Impact?

Choose Impact Air Systems as your recycling equipment partner for our proven expertise in air-based separation and conveying technology, delivering efficient, reliable solutions that improve material recovery, reduce contamination, and future-proof your operations in line with evolving recycling standards.

- Over 35 Years of Industry Expertise: Proven track record in air-based waste extraction, dust control and resource recovery solutions.

- Engineered for Performance & Efficiency: Precision-designed systems that reduce downtime and improve production efficiency.

- Leaders in Sustainable Recovery: Innovative technology that boosts recycling rates and cuts landfill waste.

- Custom-Built Solutions: Every system is tailored to meet the unique demands of your facility and materials.

- End-to-End Project Support: From concept and design to installation, commissioning, and ongoing maintenance and servicing.

- Try Before You Buy: Test your material at our Resource Recovery Demonstration Facility.

- Future-Proof Investment: Scalable systems designed to grow with your business and meet evolving regulations.

- Comprehensive training, support, and a dedicated after-sales service team

Our Reviews

Find out what our clients say about Impact

Related Solutions

Find out how our other solutions can improve your processes…

Case Studies

See how we help our customers

Latest News