Advanced Glass Separation & Recovery Solutions

At Impact Air Systems, we’ve spent many years developing and refining innovative separation and recovery systems tailored specifically to the demands of the glass recycling industry. Through close collaboration with our clients, we’ve gained a deep understanding of the operational challenges faced in glass cleaning and recovery — and we’ve responded with solutions that are robust, reliable, and results-driven.

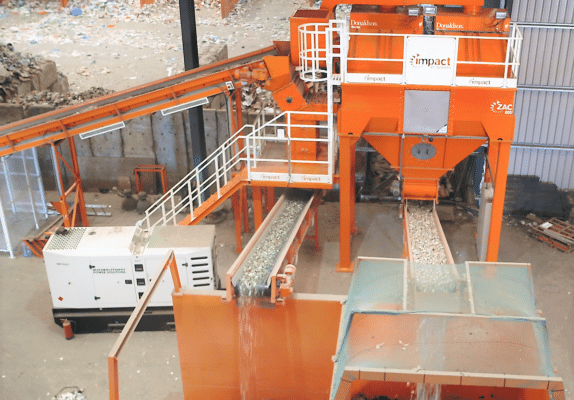

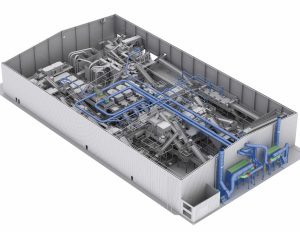

Our systems are designed to integrate seamlessly into recycling facilities, delivering high-quality glass cullet with minimal manual input, increased automation, and consistently high recovery rates.

Trusted by Industry Leaders

From independent glass processors to major MRFs, recycling plants, and waste management companies, our solutions are widely recognised and respected across the industry. Impact systems are now an essential part of glass recovery operations in facilities across the globe, helping customers maximise material value and streamline operations.

Turning Waste into Revenue – and Savings

With landfill tax continuing to rise, the ability to recover valuable glass cullet from mixed waste streams delivers not only environmental benefits but significant cost savings. Our systems help customers divert thousands of tonnes of recyclable glass from landfill every year — reducing disposal costs, boosting recycling rates, and contributing to a more sustainable operation.

Innovating for the Future – The Zigzag Air Classifier (ZAC)

As part of our ongoing commitment to innovation, we’ve re-engineered our popular Zigzag Separation System to better meet the rigorous demands of glass recycling. The result is the Zigzag Air Classifier (ZAC) — a next-generation separation system offering:

- Exceptional resistance to abrasive materials

- Fewer moving parts for lower maintenance

- Latest filtration technology for clean, efficient performance

- Outstanding separation efficiency across a wide range of applications

This upgraded design reflects our focus on durability, simplicity, and performance — all while maintaining the highest quality output that our clients expect.

Why Choose Impact Air Systems?

- Proven expertise in glass recycling applications

- Tailored systems that maximise recovery and minimise downtime

- Cost-saving solutions through landfill diversion

- Innovative technologies built for long-term performance

- Global experience and trusted industry partnerships

Talk to our technical sales team today to find out how an Impact system can improve your glass recovery process.

Watch Our Systems in Action Here

For more videos visit our youtube channel

Glass Decontamination for Re-melt and Re-use

The Impact Zigzag Air Classifier uses specialist air technologies to separate the heavy material from the light material to provide the client with a contaminant free product for recycling (remelt).

Dust, fibres and plastic are removed from the material stream leaving only glass which will then be further processed by an optical sorter prior to remelt.

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.