Leading the Way in Waste Recovery & Recycling Equipment Solutions

As global industries accelerate toward a circular economy, Impact Air Systems leads the way in designing and manufacturing cutting-edge recycling equipment and recycling machinery for the modern waste management sector. Our advanced automated recycling systems use air-based technology to separate, recover, and reclaim valuable materials—including plastics, metals, glass, paper, and fibres—from domestic, commercial, and industrial waste streams with exceptional precision and efficiency.

Whether you’re building a new recycling facility or upgrading your existing waste management operation, our bespoke recycling solutions are trusted by industry leaders worldwide. Impact Air Systems’ recycling equipment is engineered to maximise material recovery, minimise environmental impact, and increase operational profitability.

By choosing our innovative recycling machinery, you’re investing in sustainability, performance, and long-term value—helping your business meet its net-zero and environmental goals while contributing to a cleaner, more resource-efficient future.

Over 35 Years of Proven Expertise in Recycling Equipment & Waste Recovery Machinery

With more than three decades of innovation in air-based extraction, recycling equipment, and material separation technology, Impact Air Systems has established itself as a global leader in waste recovery solutions. Our experience spans industries including recycling, manufacturing, materials recovery, and environmental management, where we deliver high-performance recycling machinery tailored to each client’s operational goals.

Our recycling systems are engineered to deliver:

- Maximum recovery of recyclable materials through precision air separation technology

- Significant reductions in landfill waste and material contamination

- Lower operating costs and higher process efficiency across all recycling operations

- Enhanced sustainability and full environmental compliance with global standards

At Impact Air Systems, we combine decades of technical expertise with continuous innovation to ensure every system delivers reliable, measurable results.

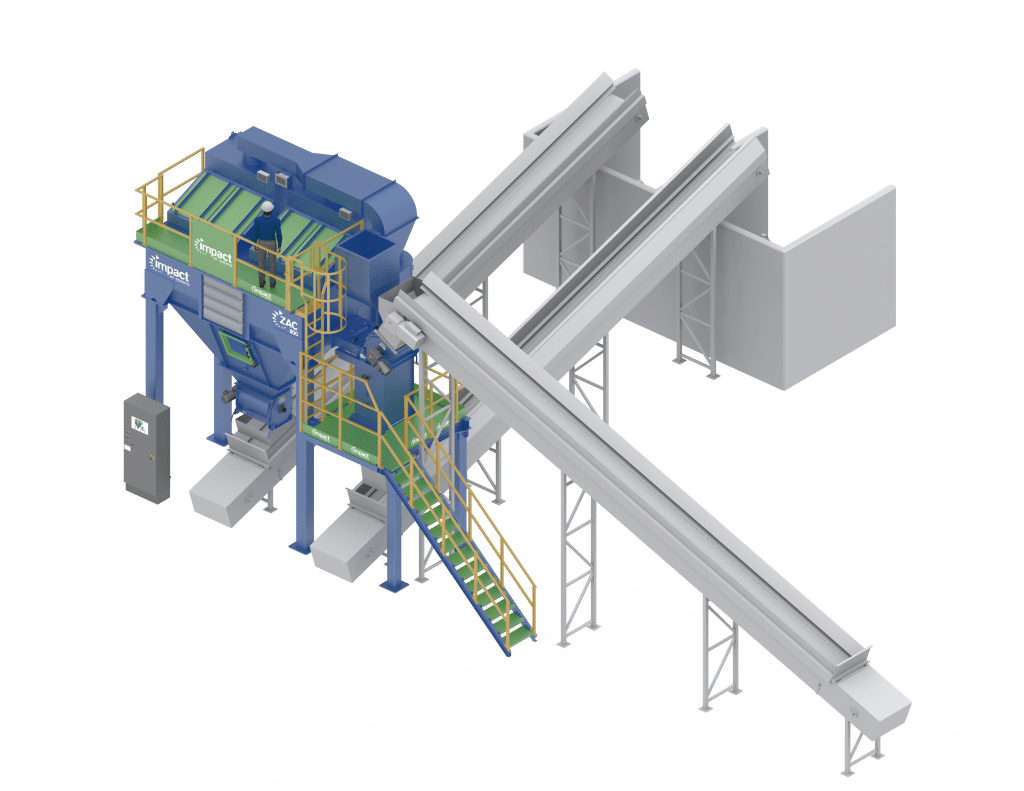

Zigzag Air Classifier (ZAC)

High-precision density separation for fine and light materials. The ZAC system delivers superior separation efficiency using cascading air columns to remove low-value contaminants from valuable recyclable fractions. Ideal for materials like fibre, plastic flakes, rubber crumb, and WEEE.

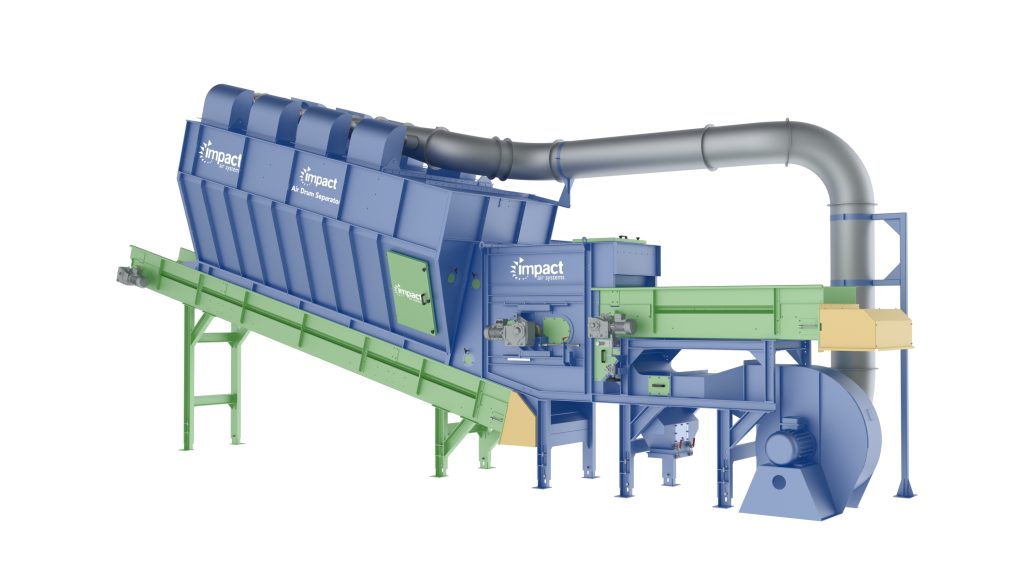

Air Drum Separator (ADS)

A robust, compact solution for light vs heavy material separation. The ADS uses controlled airflows and rotating drum technology to split materials by density, ensuring clean, consistent separation of films, foils, organics, and inert materials—perfect for DMR, RDF/SRF, and compost screening lines.

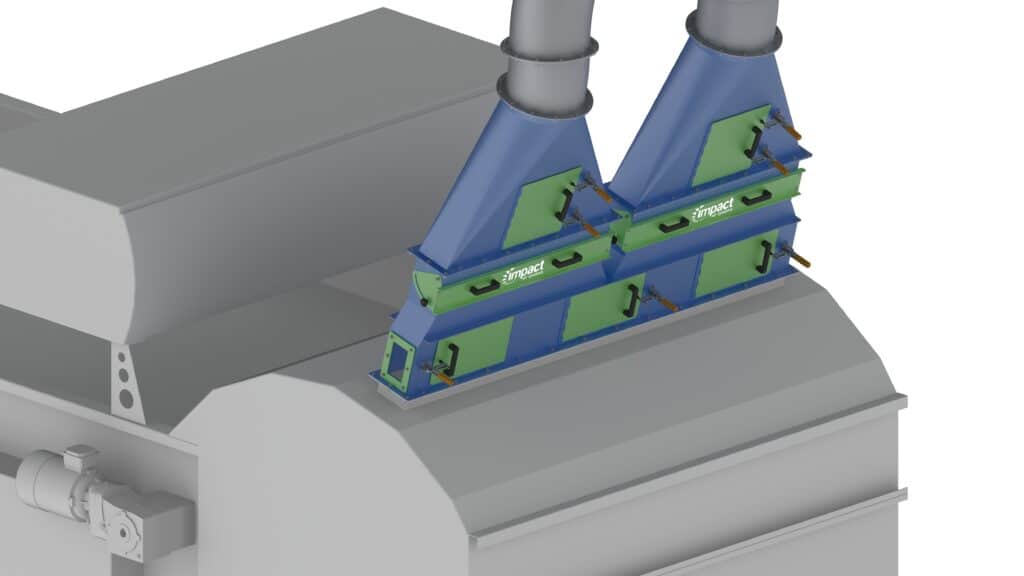

FilmLift – Plastic Packaging Capture System

Revolutionising optical sorting lines, the FilmLift system is engineered to target and extract lightweight plastic film waste rejected by air injection sorters. Designed to lift, separate, and isolate film from the rejected stream, improving fibre purity and reducing plastic contamination.

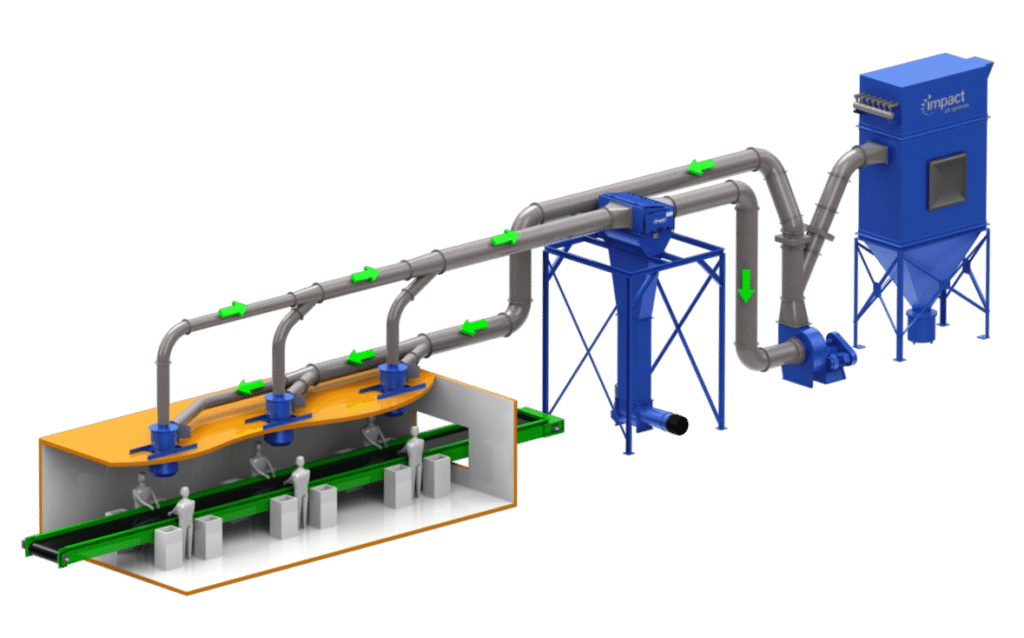

Film Vacuum System (FilmVac)

A highly effective operator-assisted solution for manual removal of plastic films and bags. Ergonomically positioned hoods effortlessly capture offered film waste with minimal noise and maximum efficiency. Ideal for MRFs, commercial laundries, e-commerce and fulfilment centres—reduces contamination and increases baling productivity.

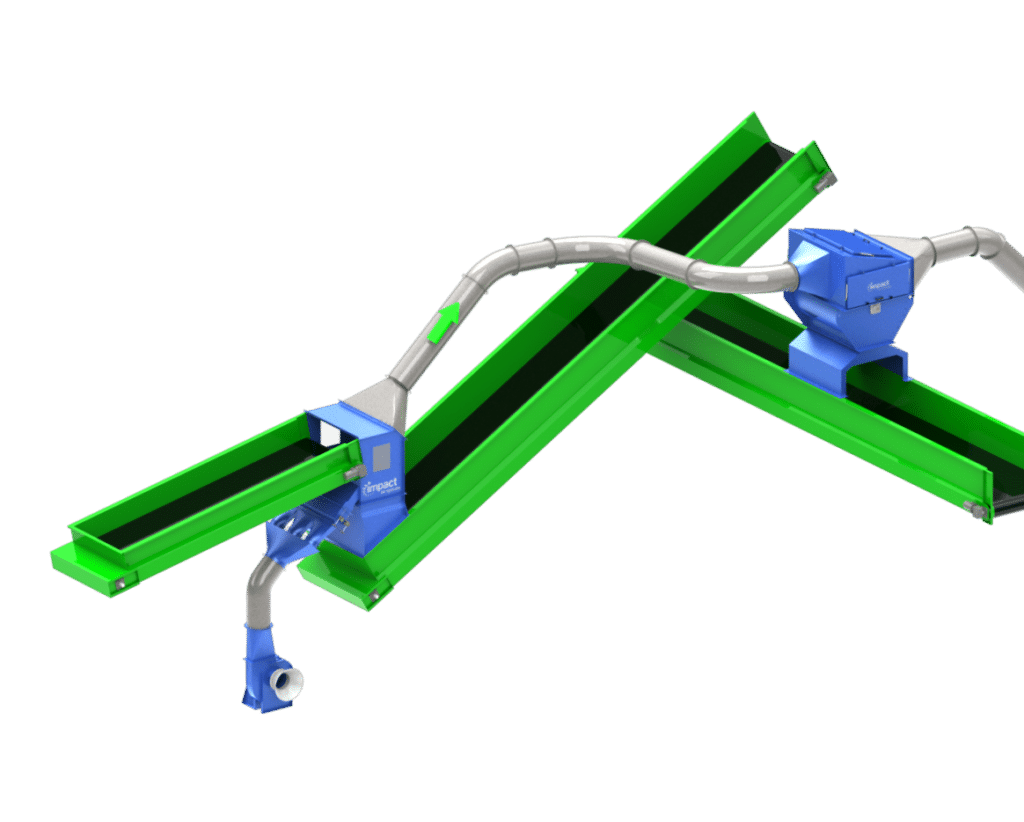

Airknife Windsifter Separator

Engineered for high-performance lightweight material removal, the Airknife uses a powerful, adjustable air jet and extraction hood to clean the material stream of foil, paper, and film at conveyor drop points. Boosts recovery quality and throughput in MRFs, C&D sites, and waste-to-energy pre-processing.

Proven Results: Demonstration Facility Access

At our dedicated Demonstration Facility in Leicester, waste managers can trial their own material samples and experience the performance of our solutions first-hand. This provides a true ‘try before you buy’ opportunity that shows exactly how our systems:

- Improve separation and recovery rates

- Minimise Loss on Ignition (LOI) to access lower tax bands

- Deliver rapid ROI—often within just a few months

Customer Success: Real-World Results

“We are so pleased with the reduced LOI rate of just 6% we now get from our material—and it’s all down to the efficient waste separation from Impact’s ZAC system. I highly recommend this solution to all waste operators.”

— Paul Lock, Managing Director, Hadley’s Recycling & Waste Management

Tailored to Your Needs

Every solution we design is bespoke—configured to fit your specific site, waste streams and recovery goals. From plastic film to dense material separation, our systems work seamlessly across the recycling and waste management sector.

Ready to Transform Your Waste Recovery Process?

Join the growing number of recycling professionals and waste facility operators who rely on Impact Air Systems to reduce waste, boost recovery, and drive profit.

Contact our technical sales team today to discuss your project and book a visit to our Demonstration Facility.

Watch Our Systems in Action Here

For more videos visit our youtube channel

Industrial Ventilation Solutions

SUEZ selected Impact to provide a solution to recover glass and SRF from the waste stream at its Avonmouth Waste Management facility.

The Impact Zigzag Air Classifier (ZAC) was the ideal solution with its highly effective separation of material based on density and shape, its ability to achieve high hourly throughput levels and ability to significantly improve the separation of the material stream.

Glass and SRF Recovery with Impact Air Systems ZAC solution!

See how the Impact ZAC separates waste materials, resulting in a more valuable material stream for the waste operator. Suitable for a wide range of applications and material throughputs. Recycling solutions for zero waste!

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.