Smart Separation for Modern Recycling

At Impact, we’ve developed a suite of advanced systems to tackle today’s recycling challenges. From our Zigzag Air Classifier (ZAC) and FilmVac & FilmLift systems to Windshifter solutions, every innovation is designed to maximise material recovery, improve quality, and streamline operations.

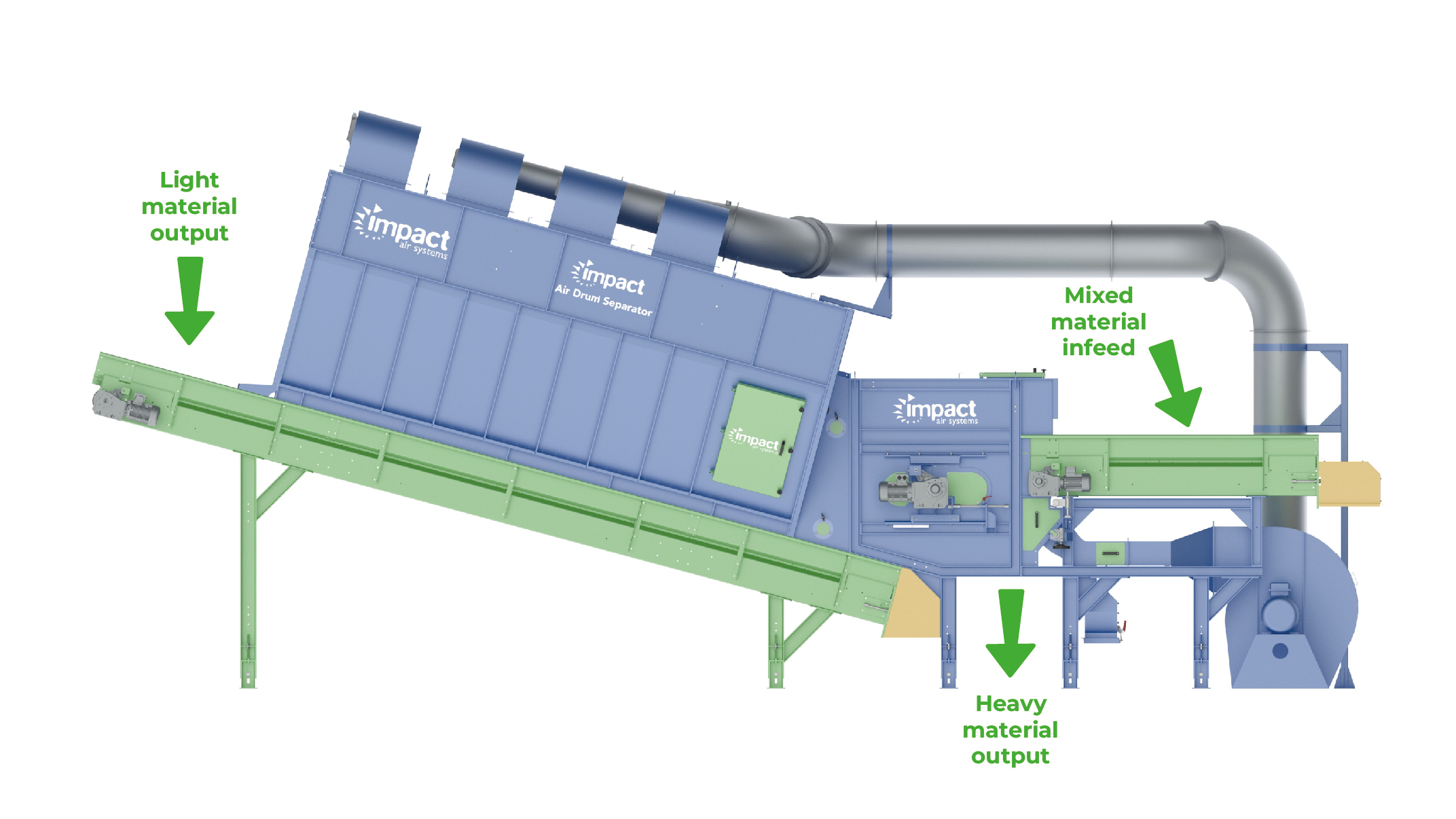

One standout technology is our newly enhanced Air Drum Separator (ADS). Engineered through a full redesign process, the ADS sets a new standard for flexibility, efficiency and reliability.

Refined for Performance: The Next-Gen ADS

Recycling operations are under pressure to deliver cleaner, higher-value materials while managing costs and staying ahead of regulation. The next-gen ADS was built to meet these challenges head-on.

Whether handling MSW, RDF, SRF, C&D, or ASR, the ADS consistently delivers outstanding results. Designed to separate mixed material streams into lights and heavies, it offers precise, high-capacity performance while being simple to operate and maintain.

The result? Better quality outputs, greater recovery rates, and improved bottom lines.

How We Engineer the Edge

At Impact, every detail is deliberate. Our design engineers work closely with customers and plant designers to ensure that each system performs reliably and efficiently across varying material streams and operating conditions. This collaborative approach results in machines that are practical, precise, and future-ready.

Key Advantages:

- Excellent separation of light and heavy fractions

- High throughput with low energy consumption

- Easy to operate, clean, and maintain

- Adaptable to different material types and site setups

- Quick return on investment through increased recovery and reduced landfill

Engineering Excellence: What’s Inside the ADS?

With three standard widths—900mm, 1200mm, and 1500mm—and throughput capacity from 20 to 250m³/hr, the ADS is tailored for performance.

Advanced features include:

- Adjustable drum movement for flexible separation

- Variable-angle air nozzles for precision control

- Energy-efficient primary fan with VFD control

- ATEX-compliant integrated dust control

- Self-cleaning drum and belt scrapers

- Secondary vacuum fan for optimal pressure balance

Everything about the ADS is engineered to maximise uptime, performance and ease of use.

Designed for Versatility: Where the ADS Excels

The versatility of the ADS makes it ideal for a wide range of recycling and recovery applications. Whether separating plastics, light paper, foils, insulation, or similar light materials, the system delivers robust performance across the board.

Common Applications:

- Municipal Solid Waste (MSW): Separate valuable recyclables from fines and organics

- Construction & Demolition (C&D): Remove insulation, films, and packaging from rubble

- Commercial & Industrial (C&I): Improve recovery of flexible plastics and papers

- Solid Recovered Fuel (SRF) & Refuse Derived Fuel (RDF): Enhance calorific value by removing contaminants including aggregates

- Biomass: Clean wood streams for efficient combustion or processing

- Automotive Shredder Residue (ASR): Pre-clean for downstream recovery or processing

Inside the Innovation: R&D Insights

“The next-gen ADS is the result of months of iterative development and real-world testing,” says Dave Lansdell, Technical Sales Director at Impact. “Our goal was to simplify operation while enhancing precision—especially for difficult or variable feedstocks. This input from frontline engineers and industry partners has shaped a system that not only works better—but works smarter.”

Real-World Results: ENVA Case Study

At ENVA’s plastics recovery facility based in Bourne, Lincolnshire, the Air Drum Separator proved its value fast.

“Impact’s ADS has been a fantastic addition to our process,” says Bernard McCulloch, Engineering Services Manager at ENVA. “It’s significantly improved the purity of our plastic streams and runs consistently with minimal intervention. The results have been nothing short of spectacular.”

Thanks to its performance and reliability, the ADS helped ENVA move closer to its zero-waste goals while improving operational efficiency.

More Than a Machine: Ongoing Support That Matters

Investing in an ADS means more than buying a piece of equipment—it’s entering a partnership. Our sister company, Impact Technical Services, ensures every system stays in peak condition.

With tailored maintenance contracts, quick delivery of spare parts, and a 24/7 response capability, we keep systems running efficiently long after installation. Many of our clients operate critical, high-throughput plants—our commitment is to keep them moving.

Try Before You Buy: In-House Demonstration Facility

To support customers in making confident decisions, Impact offers a fully equipped in-house demonstration facility. You can bring or send material samples to see the ADS in action—and witness the performance gains for yourself.

“When clients see the ADS run their material, they immediately understand its value,” says Andrew Vicary, Technical Sales Manager. “It’s a game-changer.”

A Global Footprint, Powered by British Engineering

With systems installed across Europe, North America, and Asia, Impact is proud to deliver British-engineered solutions on a global scale. We combine deep technical expertise with localised support to ensure every system is set up for long-term success.

Our network of regional partners, agents, and field technicians ensures that our customers receive local expertise and a personal touch, wherever they are.

Invest in the Future of Waste Recovery

The Air Drum Separator is more than a machine—it’s a strategic investment in the future of recycling. Cleaner material streams, better recovery rates, and simplified operations add up to real competitive advantage.

As regulations tighten and pressure grows to achieve circular economy goals, the right equipment matters more than ever. With the ADS, waste processors get a powerful, proven solution ready to meet tomorrow’s demands.

Visit our Air Drum Separator web page for more information.