Scrap Extraction Systems for the Can Making Industry

Our scrap extraction systems for the can manufacturing industry are designed to maximise production efficiency, reduce downtime, and improve sustainability across every stage of the process. With a proven track record of delivering high-quality, reliable, and cost-effective solutions, we help beverage can makers streamline operations and maintain peak performance.

Trusted by leading global beverage can manufacturers, our systems are already operating at the highest standards worldwide—giving you confidence in a solution that’s tested and trusted across the industry.

Scrap Handling & Process Extraction Solutions

Bespoke Solutions for the Metal Packaging Industry

With decades of expertise, we specialise in designing and installing custom scrap extraction solutions tailored to the demanding requirements of modern can production lines. Our systems ensure a clean, safe, and compliant workspace by efficiently capturing dust, fumes, and production waste. In addition, they support metal recovery and recycling, helping manufacturers reduce material costs while advancing their sustainability and ESG goals.

Whether you’re upgrading existing equipment or planning a new line, our scrap extraction systems for can making deliver performance, reliability, and long-term value.

Impact & The Metal Packaging Industry

Over 35 Years of Expertise in Air-Based Conveying Solutions

With more than 35 years of industry experience, Impact Air Systems specialises in the design, manufacture, and installation of advanced air-based material conveying systems. Our expertise covers a wide range of applications including matrix, trim, and scrap handling, as well as dust, fume, and oil mist control solutions.

Our systems are trusted by manufacturers around the world across a variety of sectors—from beverage can, aerosol and can-end production to paper, carton, and cardboard, as well as printing, film, textiles, automotive, healthcare, and materials recovery facilities.

Built on core values of quality, innovation, and customer focus, Impact Air Systems combines deep industry knowledge with leading-edge technology to deliver robust, efficient, and cost-effective solutions tailored to each client’s needs.

We are a trusted partner to many of the world’s best-known beverage can manufacturers, consultants, plant designers, and OEMs—playing a critical role in supporting clean, safe, and highly efficient production environments across global operations.

Our Reviews

Find out what our clients say about Impact

Innovation

Advanced Air and Material Handling Systems for the Can Making Industry

Our technology is tailored to seamlessly connect with high-speed can and end production lines, using intelligent design and automation to minimise downtime, maximise the recovery of recyclable materials, and enhance overall manufacturing efficiency.

From custom conveying systems to advanced dust, fume, and odour control solutions, we provide forward-thinking technologies that help can manufacturers and OEMs stay ahead of tightening environmental regulations and operational demands.

Trusted by leading global beverage can producers and packaging brands, Impact Air Systems combines innovation with proven reliability—delivering solutions that excel in the most demanding production environments.

We don’t just comply with industry standards—we help define them, supporting manufacturers with systems that improve productivity, sustainability, and long-term value.

We’re proud to work with many clients in this industry…

Industry Leader

Why choose Impact?

From increasing revenue through to enhanced aluminium recycling to creating a cleaner, safer working environment, Impact Air Systems delivers a wide range of benefits tailored to the metal packaging industry. Every system we provide is fully compliant with NFPA 654, NFPA 91, ATEX, and COSHH regulations—ensuring both performance and peace of mind.

- Over 35 years of British engineering excellence in the metal packaging sector

- Innovative, energy-efficient solutions tailored to your production needs

- Boost recyclate value with efficient aluminium and steel scrap recovery

- Capable of handling a wide variety of can sizes and shapes at line speeds up to 2,500 CPM

- Fully automated bale handling for uninterrupted production

- Significantly improved air quality through effective odour, dust, oil mist, and vapour extraction

- Custom-designed systems to fit your facility layout

- Upgrade options available for existing systems

- Durable, thermally insulated ductwork and user-friendly system controls

- Comprehensive training, support, and a dedicated after-sales service team

Worldwide Coverage

Installations for clients across the globe

We deliver advanced process extraction solutions to metal packaging manufacturers worldwide, combining cutting-edge technology with deep industry expertise to enhance efficiency, precision, and sustainability in production.

Working in close collaboration with our trusted network of trade agents and representatives, we provide dedicated local support and insight across a broad international footprint. Our presence spans key markets including Poland, Spain, Switzerland, the USA, Australia, Scandinavia, and many more.

Over the years, our systems have been implemented at numerous prestigious manufacturing sites around the world, reflecting our reputation for reliability, innovation, and excellence in the global metal packaging industry.

Process Extraction Solutions

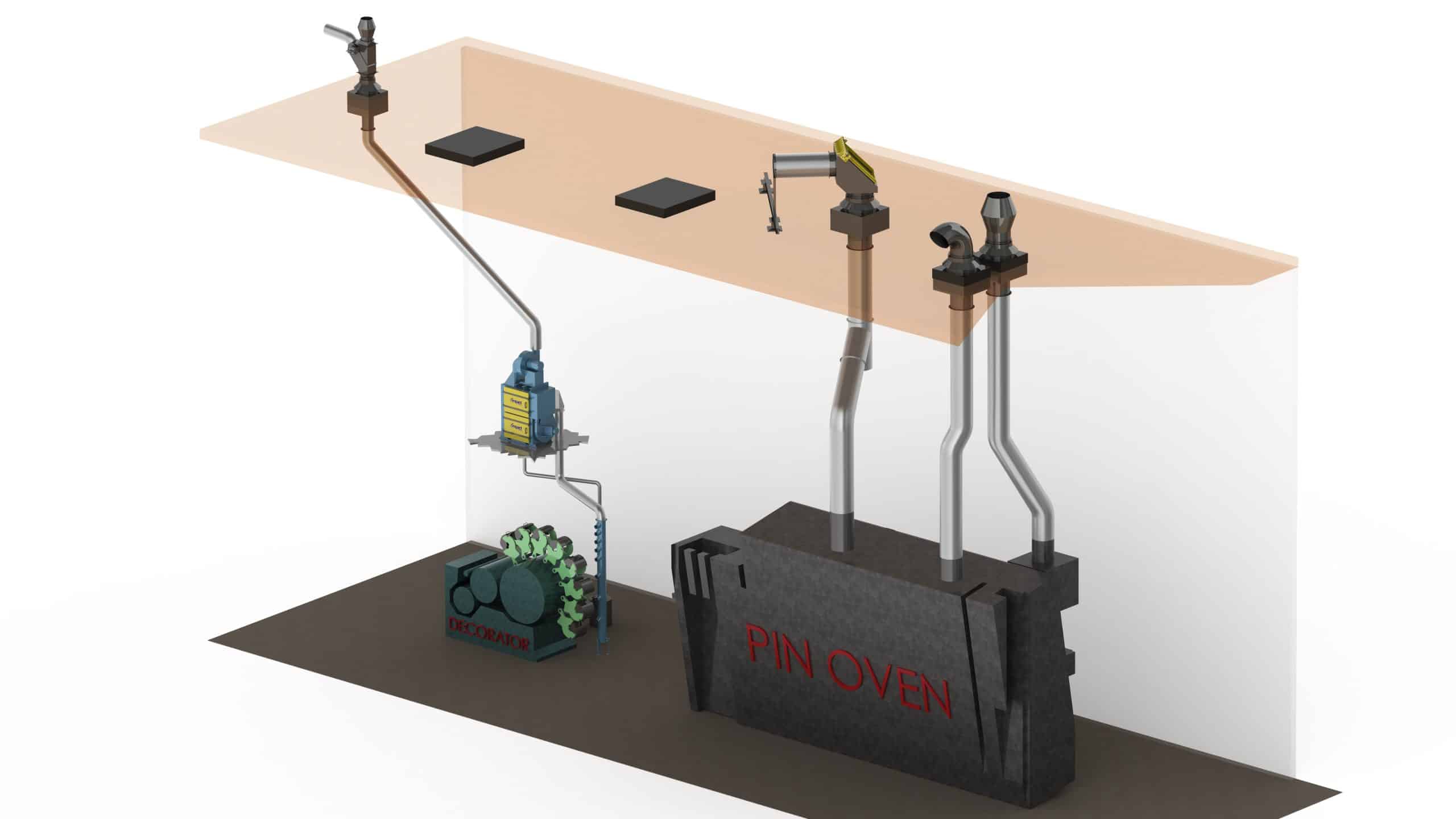

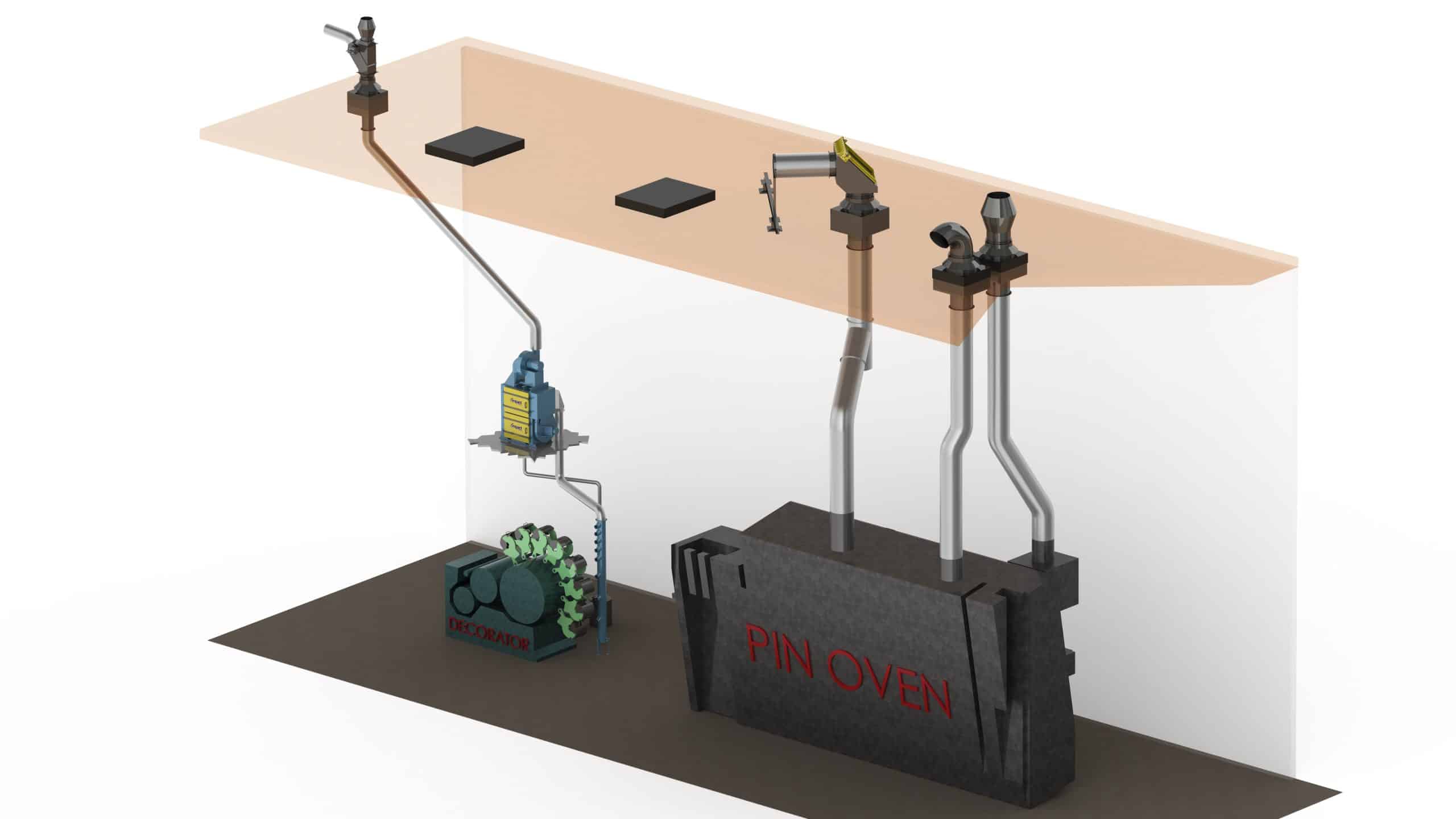

Scrap extraction and robotic bale handling

- Supports modern high-speed lines

- Backup/standby system redundancy

- Heavy duty ductwork and system components

- Energy efficient system design and ductwork layout

- Segregation of waste into bright and printed scrap

- Bale size and weight variations between bright and printed scrap

- Palletless bale stacking configuration

- Vehicle payload and after site transportation reduction

- 4 or 6 axis robot configurations

- Automatic bale stack strapping

Process Extraction Solutions

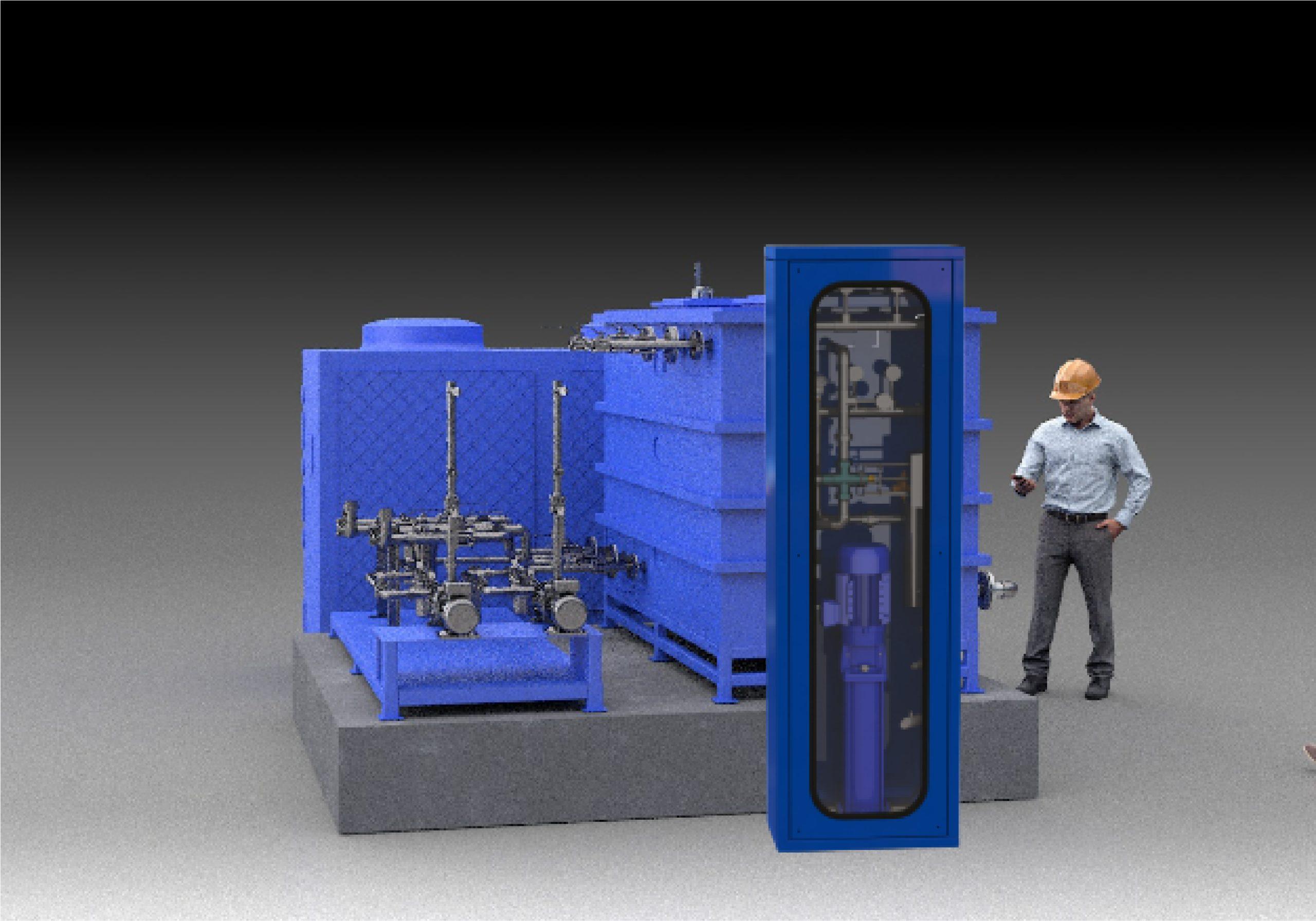

Oil Mist Extraction Systems

- Specially selected conveying ductwork with leak free joints and seals

- Local impingement filter usually mounted above the bodymaker to remove excess fluids

- Energy efficient ductwork design and conveying velocity to minimise operational running costs

- Latest hyper oil multi-stage self-cleaning filtration technology achieving a separation efficiency of 99.95MPPS according to EN1822 standards

- High efficiency clean air fans

- Easy maintenance and replacement of filtration media

Process Extraction Solutions

Printer Ink Mist & OV Mist Extraction

- Specially developed ink duct capture hoods

- Suitable for up to 8 colour printers

- Separate large droplet collector for OV mist

- Simple but effective filtration solution

- Can be ducted into cold concentrator circuit if required

Process Extraction Solutions

Printer Cooling Module

- Data logging for performance analysis

- Individual inker head and gearbox temperature control

- Can be supplied to support multiple decorators

- Automatically diverts water through a heater to avoid overcooling of the inker heads when selected low temperature is reached

Process Extraction Solutions

Sprays Lacquer and Can Conveying Fume Extraction

- Very high explosive lacquer (ATEX ST3 dust) considerations

- Specially selected ductwork earthing and electrically conductive seals or earthing bridges

- Latest technology self-cleaning dust filters

- Incorporating absolute/HEPA filter media

Process Extraction Solutions

Process Exhaust Stacks

- Data logging for performance analysis

- Individual inker head and gearbox temperature control

- Can be supplied to support multiple decorators

- Automatically diverts water through a heater to avoid overcooling of the inker heads when selected low temperature is reached

Related Solutions

Find out how our other solutions can improve your processes…

Case Studies

See how we help our customers

Latest News