Film Vacuum System – Efficient Film and Bag Removal Made Simple

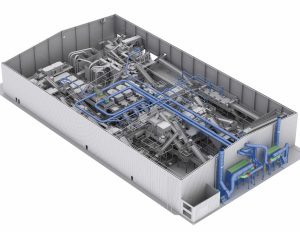

In the world of waste processing, lightweight plastic films and bags are among the most persistent and problematic contaminants. They’re hard to handle, prone to drifting, and difficult to collect manually without slowing down the sorting process. That’s why leading MRF operators are turning to the Impact Film Vacuum System—a powerful, proven solution that removes these troublesome materials quickly, cleanly, and with minimal disruption.

This system is designed specifically to target and extract plastic films and bags from waste streams, improving overall stream purity and reducing contamination in fibre and rigid plastic fractions. Whether you’re operating a high-throughput MRF or a manual sorting cabin, the Film Vacuum System delivers a seamless and scalable way to deal with low-density plastic waste.

Designed for Operator Simplicity and System Efficiency

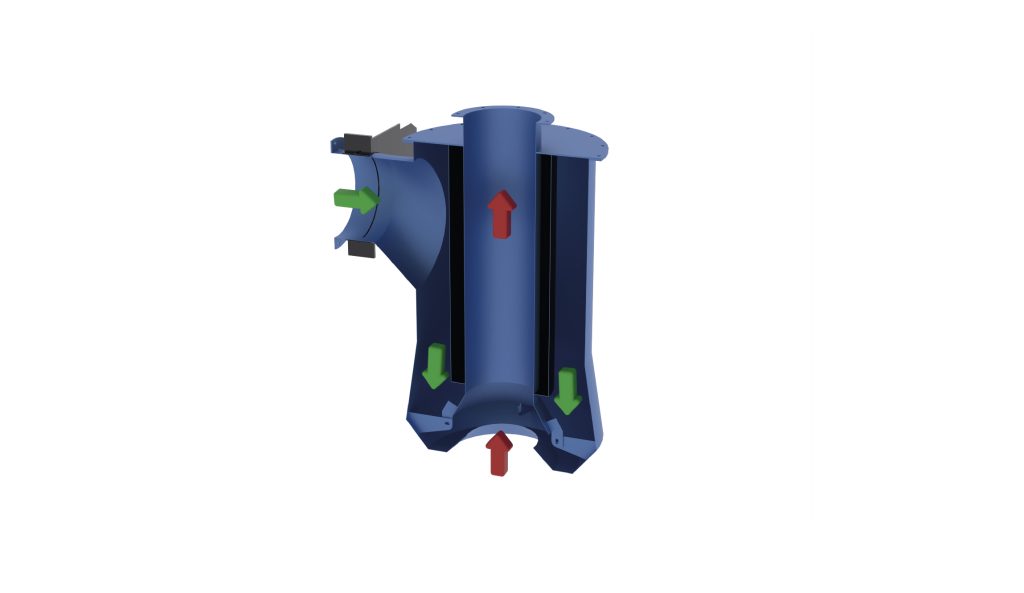

At the heart of the system is a series of uniquely engineered ‘Jetcone’ collection hoods, typically ceiling-mounted above picking belts in the sorting cabin. As operators identify film or bags on the conveyor, they simply guide the material toward the hood—no extra lifting, no conveyor stoppage, and no secondary sorting required. The film is instantly drawn into the hood via vacuum suction and transported away through a closed-loop ducting system.

Because the conveying air is recirculated, this design significantly reduces noise, lowers HVAC demand, and preserves cabin comfort, even in enclosed spaces. The closed-loop airflow ensures energy efficiency while maintaining excellent suction performance at every hood.

Multiple hoods can be linked together, allowing the system to be integrated across various sorting stations while still conveying all collected film to a single discharge point—eliminating the need for multiple storage hoppers or intermediate handling.

Delivering Real Results for MRFs Worldwide

From Europe to North America and beyond, Impact’s Film Vacuum System has been successfully deployed in MRFs looking to improve bale purity, reduce manual handling, and streamline their film collection process. It’s a simple yet transformative upgrade that brings measurable improvements in both efficiency and material quality—without requiring costly infrastructure changes.

In many facilities, the system feeds directly into a bale press or Impact screw compactor, significantly reducing the film’s volume and lowering labour and transport costs. This means more efficient storage, fewer lorry loads, and cleaner, more valuable end products.

Not Just for MRFs – A Versatile Solution Across Industries

While originally designed for recycling applications, the Film Vacuum System has also proven highly effective in e-commerce, fulfillment centres, distribution hubs, and even commercial laundries—anywhere lightweight plastics are a recurring issue.

From warehouse unpacking lines to industrial laundry processes, our film extraction technology provides a cleaner, faster, and more sustainable alternative to manual collection.

Screw Compactor – Compact, Clean, and Cost-Effective

For sites looking to further simplify handling, our optional screw compactor can be added to the Film Vacuum System. This low-maintenance unit compresses collected film into a bagged, sausage-shaped bale—ideal for direct disposal or transport. A single screw auger, discharge tube, and retaining ring deliver reliable performance at a fraction of the cost of more complex baling systems.

Why Choose Impact’s Film Vacuum System?

- Improves sorting cabin efficiency and cleanliness

- Reduces manual handling and downtime

- Increases material purity and recovery rates

- Lowers energy costs with closed-loop airflow

- Maximises ROI with minimal infrastructure disruption

Ready to Upgrade Your Film Handling Process?

Let’s talk about how the Film Vacuum System can help you capture more value from your waste stream—quickly, cleanly, and cost-effectively.

Call us on 0116 244 8855 or email sales@impactairsystems.com.

Innovative air systems, proven in practice, trusted worldwide.

Why Choose Us

-

Over 35 Years of Industry Expertise: Proven track record in air-based waste extraction, dust control and resource recovery solutions.

-

Engineered for Performance & Efficiency: Precision-designed systems that reduce downtime and improve production efficiency.

-

Leaders in Sustainable Recovery: Innovative technology that boosts recycling rates and cuts landfill waste.

-

Custom-Built Solutions: Every system is tailored to meet the unique demands of your facility and materials.

-

End-to-End Project Support: From concept and design to installation, commissioning, and ongoing maintenance and servicing.

-

Try Before You Buy: Test your material at our Resource Recovery Demonstration Facility.

-

Future-Proof Investment: Scalable systems designed to grow with your business and meet evolving regulations.

Benefits

- Engineered for poly wrap, films, plastic bags, packaging, and whole plastic bottles

- Multiple collection points feed material to a single baler or storage bunker, eliminating the need for duplicate storage

- Reduces material volume, storage space, and transport costs when used with a baler or screw compactor

- Ergonomic hood placement ensures operator comfort and easy access

- High material throughput for efficient handling of lightweight plastics

- Improves the quality of other recyclables by removing plastic contamination at source

- Quiet, closed-loop operation enhances working environment and reduces energy loss

- Low maintenance and high reliability with minimal wear parts

- Variable-length bales for easier manual handling

- No complex wire-tying systems required – simple and efficient

Watch Our Systems in Action Here

For more videos visit our youtube channel

Impact Film Vacuum System and Screw Compactor

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.