FilmVac – Automated Plastic Packaging Removal Made Simple

The Impact FilmVac System is a highly effective solution for the automatic removal of plastic bags, packing films, and backing strips from production lines or reverse logistics environments. Designed to improve operational efficiency, this flexible system helps keep workspaces clean, reduces manual handling, and prepares plastic waste for recycling through direct conveyance to a central baler.

Streamline Your Packing and Unpacking Processes

Whether during order fulfilment, product unpacking, or material returns, packaging processes often generate large volumes of plastic waste that are traditionally removed and processed manually — consuming time, labour, and valuable floor space. The FilmVac System offers a smarter alternative.

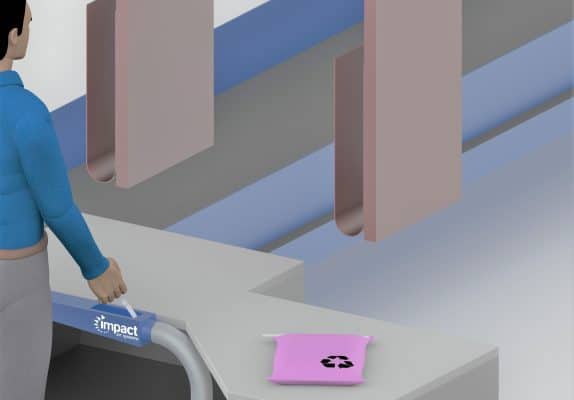

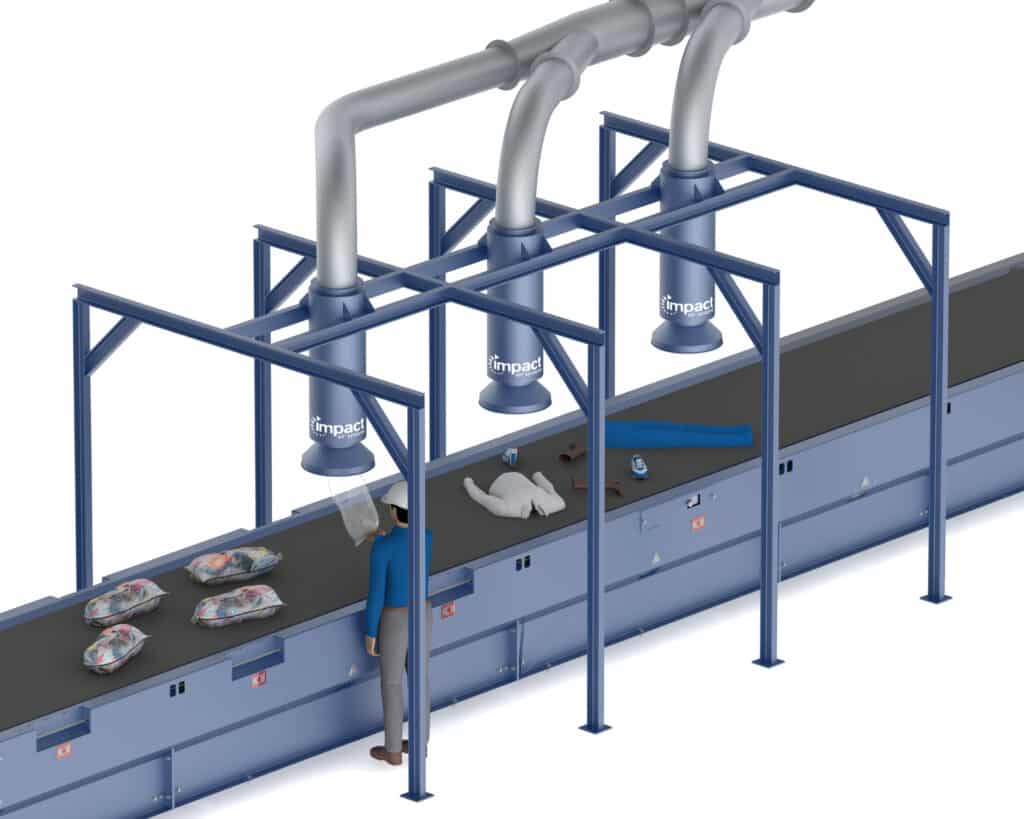

Using strategically placed return air hoods located above or near packing stations, operators can easily offer flexible plastic waste to the hood, where it is immediately extracted via vacuum and transported through ductwork to the recycling point. This not only keeps the area clean and clutter-free but also accelerates throughput and reduces handling risks.

Proven Performance Across Industries

The FilmVac System is already trusted by organisations in waste management, commercial laundry, and other industries where plastic film waste is frequent and problematic. It’s praised for its simplicity, reliability, and ability to seamlessly integrate into existing workflows — ensuring consistent performance without disrupting daily operations.

Key Benefits:

- Eliminates manual handling of plastic packaging waste

- Frees up warehouse and production space

- Improves cleanliness and safety in the working environment

- Prepares plastics for recycling via direct transfer to a baler

- Integrates effortlessly with packing benches, unpacking stations, and reverse logistics lines

- Custom-designed to suit your specific site layout and process

- Tailored to Your Operation

At Impact Air Systems, we pride ourselves on delivering bespoke solutions designed around your facility’s exact requirements. Whether you’re handling high volumes of waste packaging or looking to streamline your reverse logistics process, our FilmVac system can be configured to meet your needs.

Contact our technical sales team today to discuss your application and discover how FilmVac can transform your plastic packaging waste process.

Watch Our Systems in Action Here

For more videos visit our youtube channel

Film Vacuum System in the USA

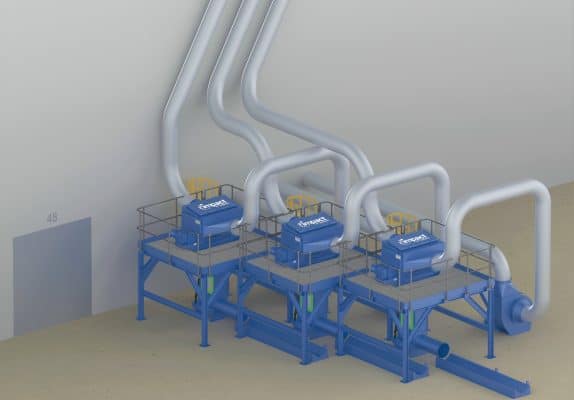

We installed a range of recyclable material recovery solutions at a waste management facility in Texas, USA. The FilmVac solution was installed to remove the plastic film and bags from the waste stream.

Once collected by the hoods located above the conveyor, the plastic is then conveyed to a screw compactor and baled into manageable ‘sausage’ like bales for recycling, resulting in plastic free waste stream which can then be further processed.

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.