Efficient Waste Extraction for the Tissue Industry

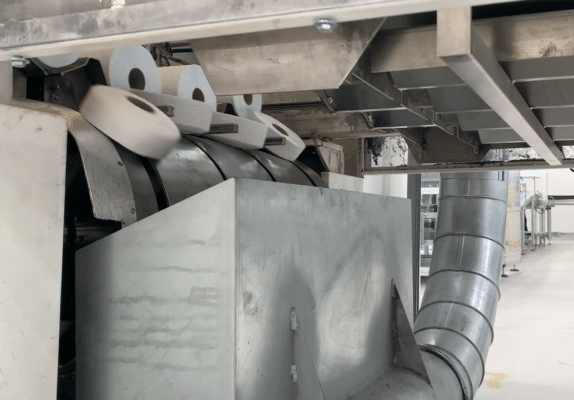

At Impact Air Systems, we understand the unique challenges faced in tissue production — from managing off-cuts and cookies to safely handling dust-heavy waste streams. Our tissue extraction systems are specifically designed to collect and convey toilet roll and kitchen roll off-cuts from log saws, delivering a cleaner, safer, and more efficient production environment.

These systems transport waste material directly to an external baling area, freeing up valuable floor space and ensuring waste is handled automatically and hygienically.

Nubbin & Cookie Collection – Smarter Waste Handling

Our innovative extraction solution allows “nubbins” or “cookies” to be captured directly at each log saw and pneumatically conveyed to a central waste area. Using a single fan per grade type, this setup simplifies infrastructure, lowers energy consumption, and reduces capital investment, while keeping the production floor free from manual waste handling equipment.

Where grade separation is required (e.g. for toilet vs. kitchen tissue), each stream can be handled by an independent system to maintain material integrity and maximise recycling potential.

Designed for Dusty Environments

Tissue production is inherently dusty — that’s why we integrate a reverse jet filter system into the airflow design. This ensures clean conveying air, reduces filter maintenance, and keeps your workplace compliant with air quality standards.

Built-In Safety: Spark Detection & Fire Suppression

Safety is a key priority in high-speed, dust-prone environments. Our systems can include spark detection and fire suppression technology to protect your facility, your staff, and your equipment — providing peace of mind around the clock.

Handling Whole Logs and Slab Waste

Impact’s solutions aren’t limited to off-cuts alone. Our systems can also be engineered to handle whole tissue logs and slab waste from the production line. Bulky materials are transported via forklift and fed onto inclined conveyors, delivering them directly to tissue balers for efficient processing.

Why Choose Impact Air Systems?

- Over 35 years of expertise in automated waste handling

- Custom-designed systems for log saw off-cuts, whole logs, and slab waste

- Minimal energy use and capital cost with centralised fan solutions

- Cleaner, safer production environments with advanced filtration

- Full compliance with safety standards thanks to optional fire protection features

Let us design a tailored solution for your tissue production facility.

Contact our technical sales team today to discuss how we can optimise your waste extraction process.

Watch Our Systems in Action Here

For more videos visit our youtube channel

Tissue Manufacturing Off-Cut Collection System

Here we remove the nubbins/cookies off cuts from the toilet roll and kitchen roll manufacturing process and pneumatically convey them to an external baler or compactor for recycling.

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.