Plasterboard Recycling Solutions

Impact Air Systems has become the go-to choice for plasterboard recycling companies across the UK, thanks to our proven expertise in density separation technology. Our systems are specifically engineered to separate gypsum from paper backing with high precision, ensuring the maximum recovery of reusable material — and helping operators achieve their zero-to-landfill goals.

Efficient Gypsum Recovery

We understand the importance of preserving valuable raw materials in a circular economy. Our separation systems allow gypsum to be recycled repeatedly, supporting sustainable operations and reducing disposal costs. With years of experience in this niche sector, we offer systems that are both robust and adaptable, ready to meet the needs of your facility.

Advanced Separation & Dust Control

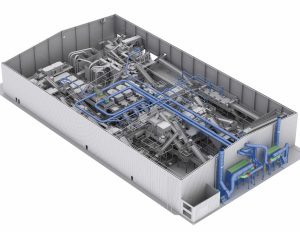

Our core systems for plasterboard recycling include:

- Zigzag Separation System – A high-efficiency air classifier that separates gypsum from paper with minimal loss

- Air Knife Separation System – An effective method for lifting and removing lightweight contaminants

- Dust Control Systems – Ensures a clean, safe working environment, capturing hazardous airborne particulates and improving workplace conditions

Together, these systems provide a complete solution for efficient, compliant, and sustainable plasterboard recycling operations.

Trusted by Industry Leaders

We’re proud to support customers like Hamilton Waste & Recycling Ltd, who had this to say:

“We are delighted with the air separation and dust extraction technology that Impact Air Systems provided for our plasterboard recycling system. Not only are we delighted with the performance of the system, but also the service we received from Impact Air, from our initial discussions through to the commissioning of the plant. Impact’s solution has certainly surpassed our expectations and we at Hamilton Waste & Recycling Ltd will be contacting Impact Air Systems for any future air separation and dust extraction systems.”

— David Hamilton, Hamilton Waste & Recycling Ltd

Why Choose Impact?

- Proven success in gypsum and paper separation

- Designed to support zero landfill objectives

- Full control of dust and airborne hazards

- Custom-engineered systems to suit any facility size

- Outstanding customer service from consultation to commissioning

Get in touch with our technical sales team to discuss how we can help optimise your plasterboard recycling process with a custom-built solution that delivers results from day one.

Watch Our Systems in Action Here

For more videos visit our youtube channel

Gypsum Recovery Solution

See how the Impact Zigzag Air Classifier (ZAC) separates gypsum nuggets, fibre and dust to provide a more valuable product.

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.