Next-Gen Air Drum Separator (ADS): Performance Refined For Exceptional Resource Recovery

As the recycling industry accelerates toward zero waste, staying competitive means more than just keeping up—it means getting ahead. That’s where the next-generation Air Drum Separator (ADS) from Impact Air Systems delivers.

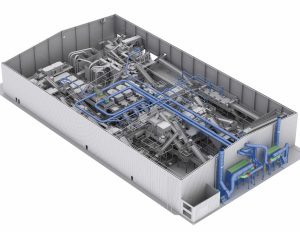

Engineered from the ground up using real-world feedback, cutting-edge design, and decades of industry expertise, the ADS redefines what’s possible in high-performance air separation. With exceptional flexibility, throughput, and reliability, this advanced system empowers operators to recover more material, reduce contamination, and streamline operations across a wide range of recycling applications.

Built for Today’s Challenges, Ready for Tomorrow

Modern waste processors face intense pressure: rising recovery targets, tighter regulations, and ever-changing material streams. The ADS is purpose-built to meet these demands—efficiently separating light fractions like plastics, film, and paper from heavier materials such as aggregates, metals, and glass.

Whether handling MSW, RDF, SRF, C&D, ASR, or biomass, the ADS delivers outstanding results in real-world conditions—boosting purity, improving throughput, and lowering disposal costs.

Why Choose the ADS?

Exceptional light/heavy separation – Accurately splits material streams to extract valuable recyclables while reducing contamination.

High throughput, low energy – Variable fan controls ensure maximum separation with minimum power consumption.

Simple to operate, clean & maintain – Designed with the operator in mind—self-cleaning systems reduce downtime and maintenance.

Adaptable for multiple waste types – Customisable settings and configurations for virtually any material or facility layout.

Fast ROI & long-term value – Increase recovery rates and reduce landfill dependency—driving profitability and sustainability.

Precision Engineering. Unmatched Performance – How it works

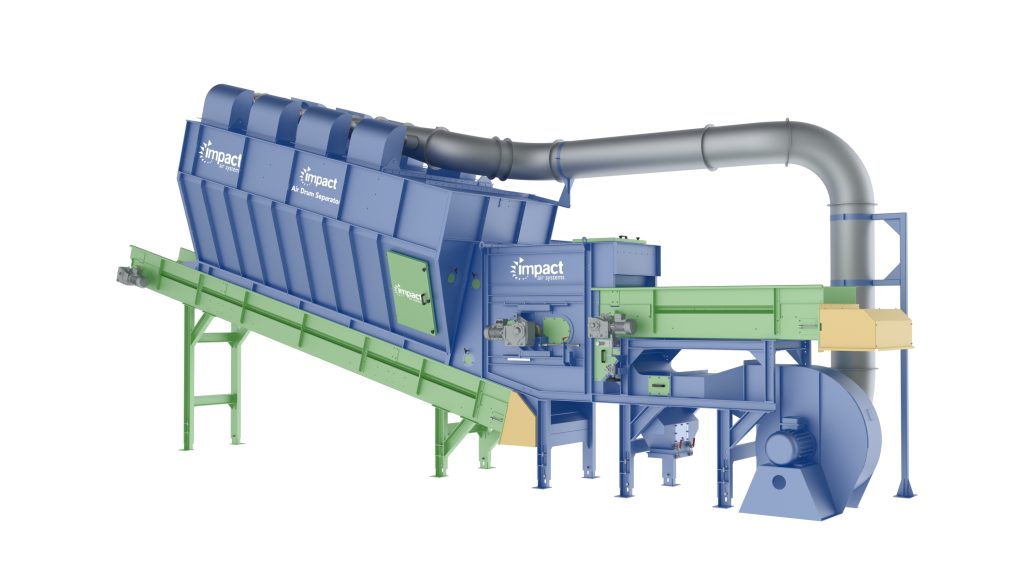

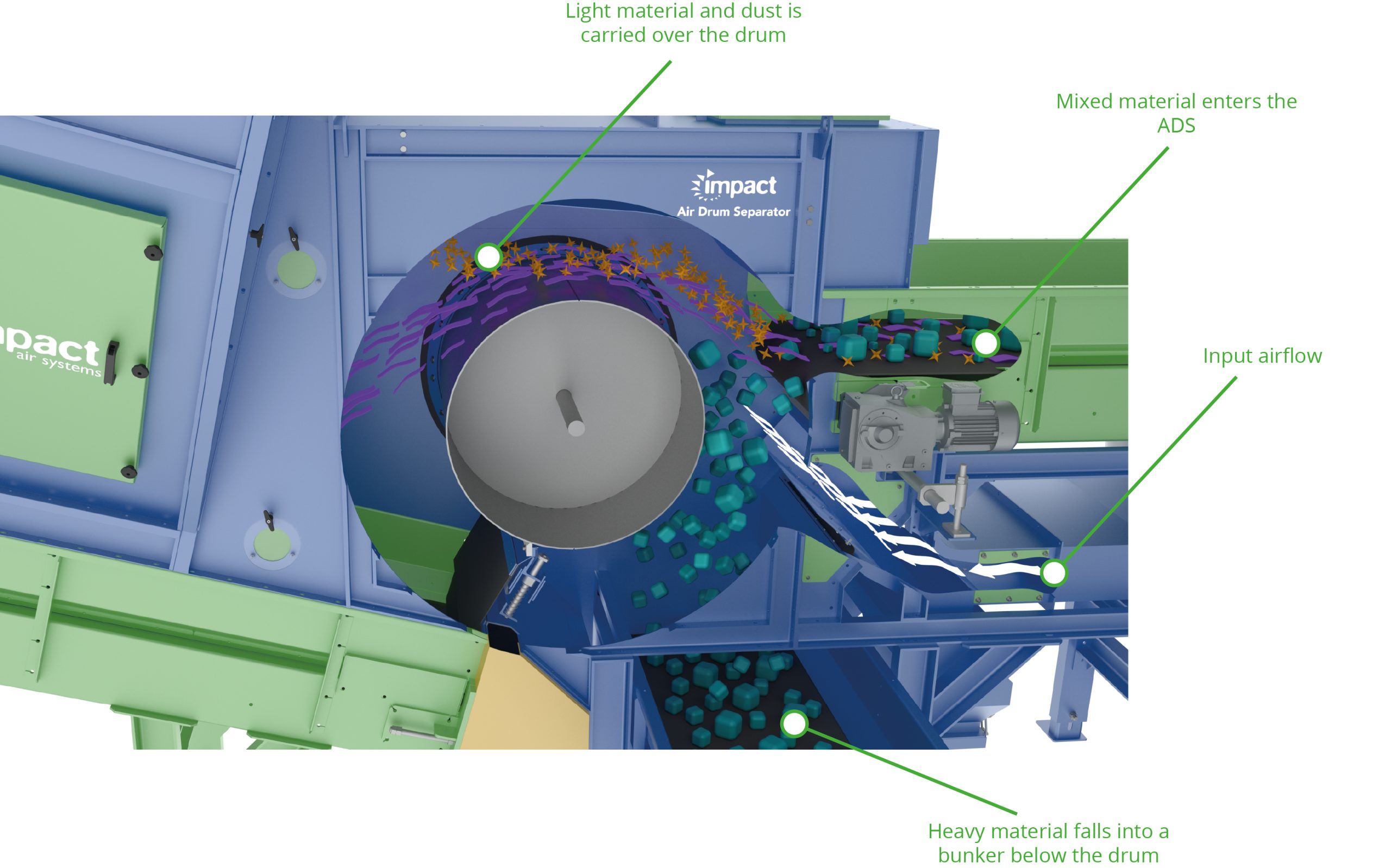

The Impact Air Drum Separator (ADS) combines high-efficiency air knife technology with a rotating drum, purpose-built for high-volume material separation. Engineered to process a wide range of materials, the ADS separates mixed waste streams based on density, shape, and aerodynamic behaviour.

Installed at the end of an in-feed conveyor, the ADS uses a precisely angled, high-velocity air knife to project a focused airstream upward. This airflow lifts lighter materials and carries them over the drum into a designated collection zone, while heavier items remain unaffected and drop out in front of the drum for separate recovery. The result is a clean, efficient separation of materials.

Offered in a variation of widths including 900mm, 1200mm, and 1500mm, with throughput capacities ranging from 20 to 250m³/hr, the ADS is both scalable and powerful. Every feature is engineered to optimise efficiency and separation quality:

- Adjustable drum movement – Fine-tune separation based on material flow

- Variable-angle air nozzles – For precise targeting of lightweight materials

- VFD-controlled primary fan – Tailor airflow for specific material profiles

- ATEX-compliant dust control – Ensures safe operation in hazardous environments

- Self-cleaning scrapers – Maintains peak performance with minimal manual cleaning

- Secondary vacuum fan – Balances pressure within the lights enclosure for clean, consistent separation

Versatility That Performs Across Industries

From plastics and fibre to insulation and foils, the ADS adapts seamlessly across a wide range of material streams:

- Municipal Solid Waste (MSW) – Extract recyclables and reduce contamination

- Construction & Demolition (C&D) – Remove foils, films, and insulation from aggregates

- Commercial & Industrial (C&I) – Improve recovery of flexible packaging and paper

- Refuse Derived Fuel (RDF) / Solid Recovered Fuel (SRF) – Increase calorific value by eliminating aggregates and dust

- Biomass – Clean wood streams for efficient fuel conversion

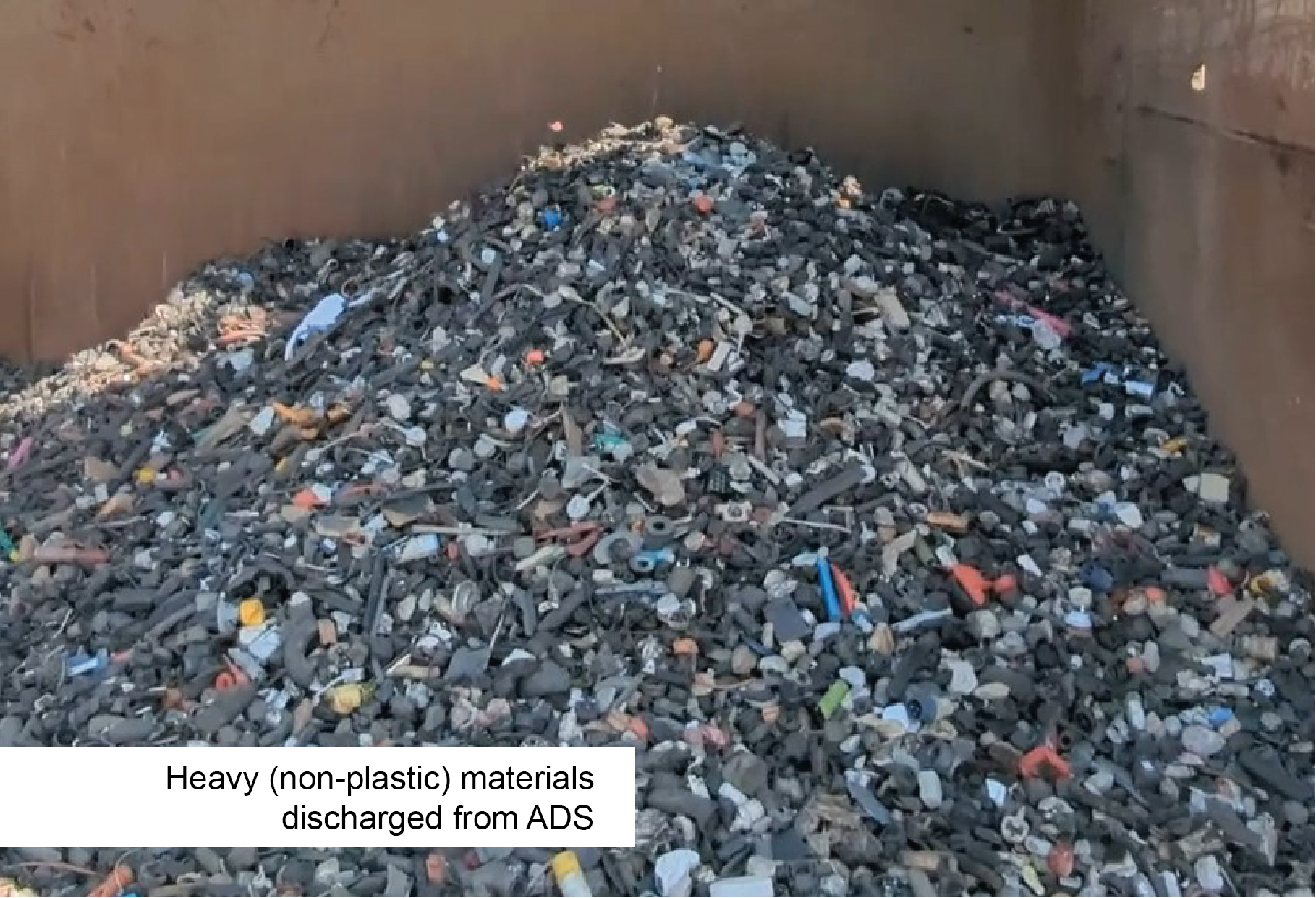

- Automotive Shredder Residue (ASR) – Pre-clean shredded materials for better downstream recovery

What Our Clients Say: ENVA Case Study

At ENVA’s plastic recovery plant in Lincolnshire, the ADS transformed processing outcomes.

“Impact’s ADS has been a fantastic addition to our process,” says Bernard McCulloch, Engineering Services Manager at ENVA. “It’s significantly improved the purity of our plastic streams and runs consistently with minimal intervention. The results have been nothing short of spectacular.”

Designed by Experts, Backed by Engineers

Every ADS system is the result of close collaboration between our design team and on-site engineers. We work hand-in-hand with clients and plant designers to build systems that fit seamlessly into existing lines—or brand new ones. It’s this practical, forward-thinking approach that makes the ADS a smarter investment.

“The next-gen ADS was developed through continuous testing and industry feedback,” says Dave Lansdell, Technical Sales Director. “It’s not just easy to use—it’s more precise, more reliable, and more effective for tough or variable feedstocks.”

See It in Action – Try Before You Buy

Want proof before you invest? Visit our in-house demonstration facility, where we test your actual materials on the ADS. See first-hand how the system performs—so you can make a confident, informed decision.

“When clients see the ADS in action with their own material, the benefits are obvious,” says Andrew Vicary, Technical Sales Manager. “It’s a game-changer.”

Ongoing Support That Keeps You Moving

With support from Impact Technical Services, your ADS system stays at peak performance long after installation. We offer:

- Tailored maintenance contracts

- Fast delivery of spare parts

- On-call for technical assistance

- On-site servicing and inspections

We help you avoid costly downtime—keeping your process running efficiently.

Globally Proven. British Engineered.

With systems installed in over 20 countries, our technology is trusted by waste processors worldwide. From Europe to North America and Asia, our UK-based design and manufacturing delivers scalable solutions with global reach—supported by a network of regional partners, agents, and service engineers.

Invest in Cleaner Streams, Better Recovery, and Long-Term Profitability

The ADS isn’t just a piece of equipment—it’s a strategic tool for waste recovery operations aiming to lead in the circular economy.

As sustainability targets tighten and operational pressures grow, your facility needs reliable, efficient, and future-proof technology. The Air Drum Separator delivers—today and for years to come.

Ready to elevate your separation process?

Call 0116 244 8855 or email sales@impactairsystems.com to speak with our technical team.

Benefits

- Exceptional density separation for cleaner, high-purity material streams

- Maximises material value, boosting overall profit potential

- Rapid return on investment with competitive pricing and low operating costs

- Cuts landfill fees by diverting more recoverable material

- High-capacity throughput to meet the demands of modern recycling operations

- User-friendly interface with intuitive controls for effortless operation

- Customisable settings for precise performance and optimal results

Watch Our Systems in Action Here

For more videos visit our youtube channel

Air Drum Separator (ADS) Windshifter | Smarter Material Separation for Recycling

Windshifter Material Separator | Reliable Sorting for Complex Streams

Our Latest Case Studies

Explore our latest case studies showcasing innovative solutions and measurable success, highlighting our expertise in delivering impactful results for businesses across diverse industries.